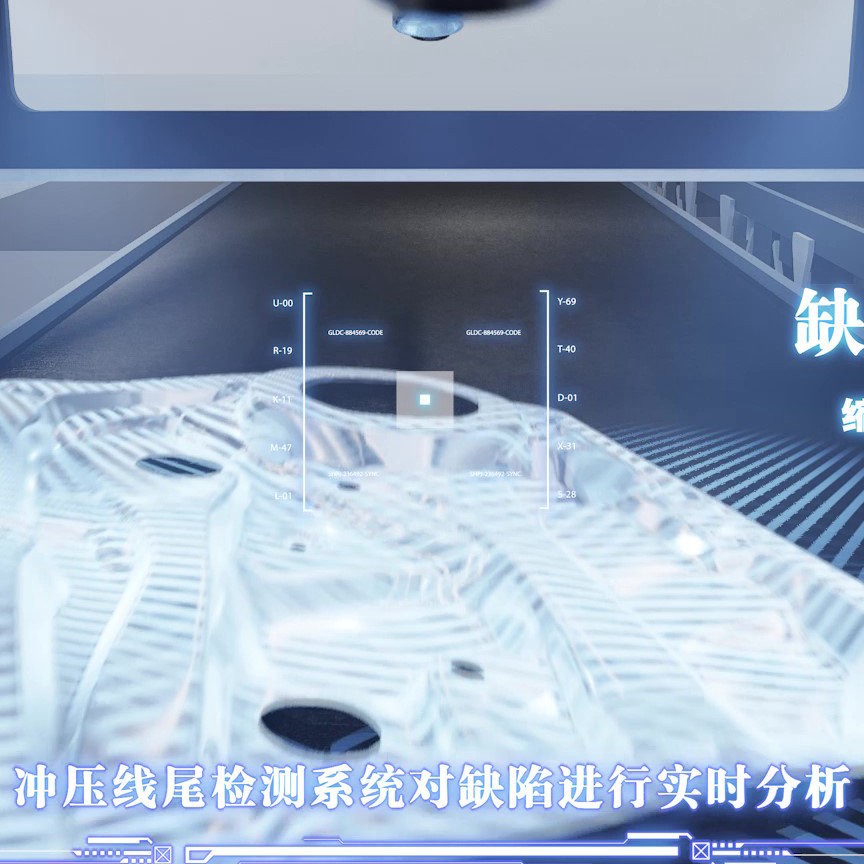

At present, the detection of finished parts is still based on visual detection by personnel at the end of the press line. Due to a large number of defects in the parts and the complex standards, the training period for the visual inspectors of this part is long and costly, and each person has a different understanding of the defect standards, which also results in inconsistent detection standards. This traditional detection method has become increasingly unsuitable for modern production.

The automatic coding system at the end of the line forms individual traceability of the pressed parts, which can be associated with stamping process information and defect information, while the QR code can be associated with the frame number to improve the traceability of the whole vehicle.

The automatic coding system at the end of the line forms individual traceability of the pressed parts, which can be associated with stamping process information and defect information, while the QR code can be associated with the frame number to improve the traceability of the whole vehicle.