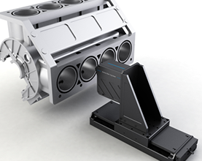

Visual inspection of engine block and cylinder head

The cylinder belongs to the aluminum die-casting parts which will be poured with high-temperature aluminum water into the forming mold, caused by the mold or insufficient temperature of molten metal, metal mixed with impurities, too little vent, too much lubricant, and other reasons such as porosity, shrinkage, thermal crack, and flow marks and other defects, in its machining, it will cause a bump, scratch, and knife pattern defects on the surface of the product.

Solutions

When the cylinder block comes out from the front cleaning machine, the part enters the visual detection station on the production roller conveyor, a mechanical arm is set up at both ends of the detection station, the mechanical arm drives the industrial camera and custom multi-angle ring light source to collect images of the cylinder block processing surface according to the designed walking path, multiple images are collected at the same location of the part, multiple images are combined into a single image using traditional algorithms (photometric method), the detection software uses AI models to reason about the images, determine whether they are qualified, screen defects of different sizes in different detection areas, achieve accurate screening and judgment of defects, and at the same time bind the detection information to the part QR code and upload it to the on-site MES system.

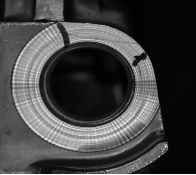

Fitow uses a robotic arm to grip the inner wall measuring equipment to scan the bore of the cylinder block and generate detection results in combination with its algorithms. As the measurement process is non-contact, errors caused by gauge use and wear and tear are reduced, improving detection accuracy and efficiency.

Function realization