AGV mobile inspection

In order to realize the intelligent transformation of the whole process of the production line, the intelligent inspection scheme is adopted in the three workshops of the famous intelligent production line.

Based on a domestic intelligent production line for intelligent search and docking deployment

The result of machine inspection is better than that of manual inspection

Customer side detection rules are not unified, manual inspection easily missed detection items, staff inspection time is long

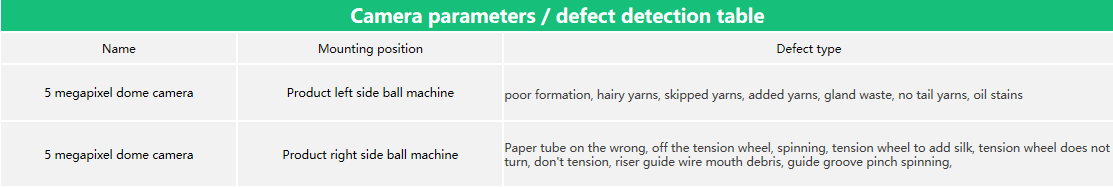

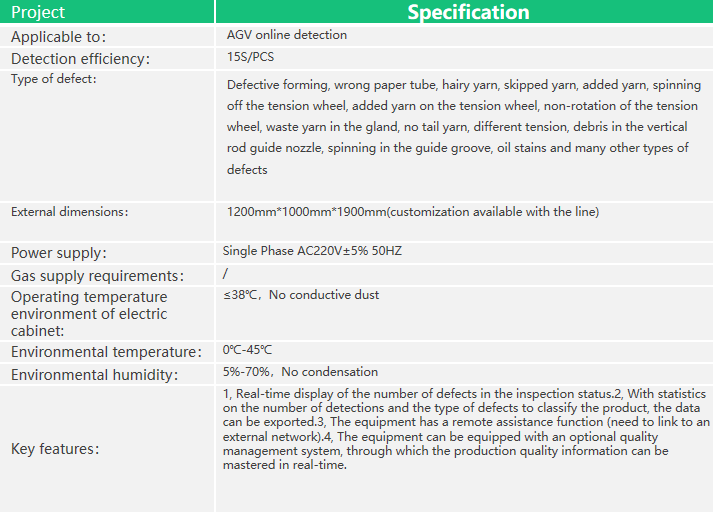

Inspection of defects, such as bad molding, paper tube fault, woolen yarn, skipping, adding, spinning with tension wheel, adding with tension wheel, non-rotating with tension wheel, waste covered yarn, non-tail yarn, non-tension, sundries of guide rod, crevice spinning with guide groove, oil stain and so on

The status of the industry

Fitt Technologies

Compatibility

Double ball machine with many detectable items

Focused Inspection

Manual intervention for key locations

15 Sec

Complete process for detecting individual filaments in 15 seconds

Low downgrade

Help customers sort out manual defect detection criteria for detection during production to reduce the detection rate of defects in finished products.

Rapid deployment

Deployment, commissioning and acceptance within 2 months

Dome parameters introduction. Support maximum 2560×1440@30fps HD screen output.

Adopt high efficiency fill the light array, low power consumption, infrared fill light 150m

Built-in heating glass, effective defogging.

Support ultra-low illumination, 0.005Lux/F1.2(color),0.001Lux/F1.2(B/W),0 Lux with IR

32x optical zoom, 16x digital zoom

support 3D digital noise reduction, 120dB wide dynamic

IP66, strong anti-interference capability, suitable for the harsh electromagnetic environment, comply with GB/T17626.2/3/4/5/6 level 4 standard

Adopt high efficiency fill the light array, low power consumption, infrared fill light 150m

Built-in heating glass, effective defogging.

Support ultra-low illumination, 0.005Lux/F1.2(color),0.001Lux/F1.2(B/W),0 Lux with IR

32x optical zoom, 16x digital zoom

support 3D digital noise reduction, 120dB wide dynamic

IP66, strong anti-interference capability, suitable for the harsh electromagnetic environment,