3D weld detection

Welding is a manufacturing process and technique for joining metals or other thermoplastic materials utilizing heat, high temperature, or pressure and is widely used in industrial production.

Project Overview

Visual detection of all parts in the subsequent welding process can be time-consuming and even highly skilled and experienced inspectors can miss minor defects and make human errors. In recent years, with technological innovations, there has been a growing trend toward non-contact detection using "laser displacement sensors", which can automatically inspect at high speed and with high accuracy in-line, in the factory automation industry, which demands higher speed and quality in mass production.

solution

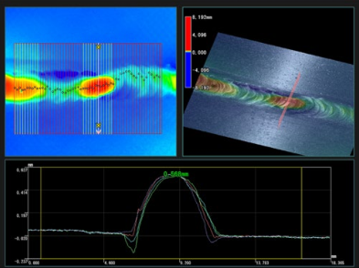

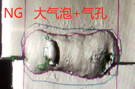

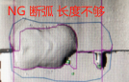

Non-contact surface detection by means of a 3D laser sensor. By shining structured light onto the weld surface and using the feedback formed by the reflection, 3D image data of the weld area is acquired, and, together with Fitow's self-developed AI defect recognition algorithm, the quality of the weld is inspected.

3D weld detection hardware parameters

A 3D camera is used to photograph the weld area, with two surface array cameras and structured light forming a 3D point cloud of data. The 3D image is captured with height information so that the z-directional seam height of the weld can be measured.