Gear visual detection equipment uses high-definition industrial cameras with special light sources to provide a professional visual environment, while with automated workpiece rotation, defects on the transmission gear end face, tooth inner wall, tooth top, and tooth bottom can easily be clearly presented in the image, such as a bump, rust, black skin, and other defects, and then with mechanical arm loading and unloading to achieve unmanned automated detection.

- FRONT PAGE

-

AUTOMOBILE INDUSTRY

- Gear shaft visual inspection

- Visual inspection of engine block and cylinder head

- Extruded Part Inspection

- Unwinding detection

- Mold Monitor

- Mold temperature monitor

- Personnel entry and exit safety monitoring

- End-of-line visual inspection system

- Electrode Cap Vision Inspection System

- 3D Weld Inspection

- 3D Welding Vision Guide

- Paint shop

- Assembly workshop

- CHEMICAL FIBER AND TEXTILE INDUSTRY

- 5+4 Technology Platform

- PRODUCTION COLLABORATION PLATFORM

- SMART HARDWARE

- About FITOW

Gear shaft visual inspection

Solutions

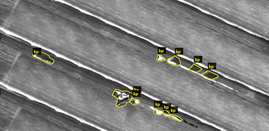

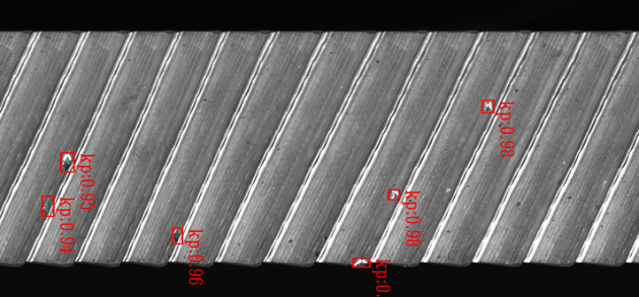

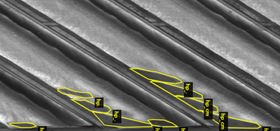

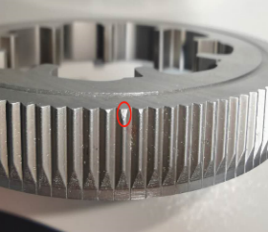

Gear visual detection equipment uses high-definition industrial cameras with special light sources to provide a professional visual environment, while with automated workpiece rotation, defects on the transmission gear end face, tooth inner wall, tooth top, and tooth bottom can easily be clearly presented in the image, such as a bump, rust, black skin, and other defects, and then with mechanical arm loading and unloading to achieve unmanned automated detection.

Defect picture

Company Address:Floor 1-3, South Building, Tianjin Zhihuigu Artificial Intelligence Industrial Park, No. 28 West Seventh Road, Tianjin Pilot Free Trade Zone (Airport Economic Zone)

FITOW Service Hotline

+86 22 84958362

Fitow(Tianjin) Testing Technology Co., Ltd.

WeChat public account: Fitow Tianjin Testing Technology Co., Ltd.