Project Overview

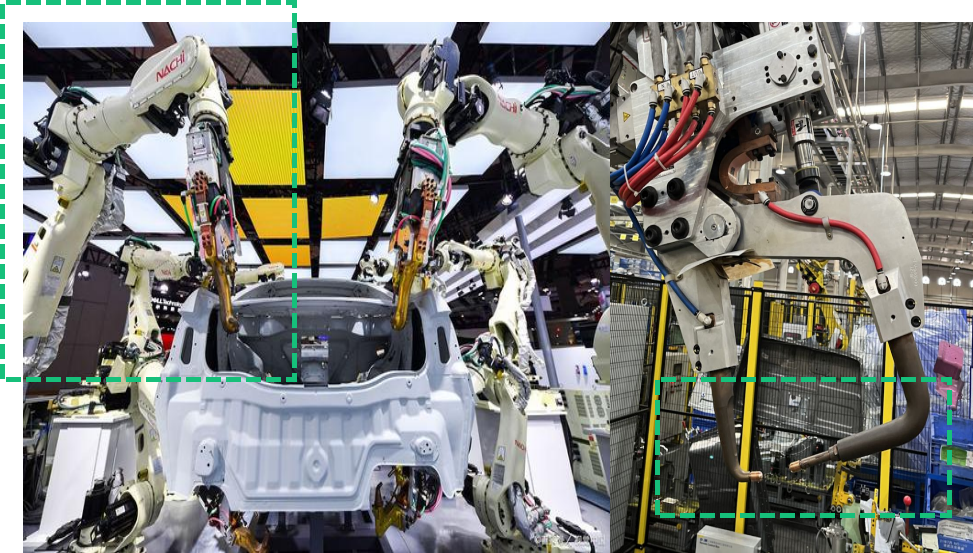

Electrode cap visual detection system

Electrode caps used for spot welding will produce an oxide layer after a period which will affect the

quality of the weld and require frequent resharpening, and too large or too small a contact area will

cause unstable current resulting in unqualified joints, uneven heating of the contact surface and

defects such as oxide inclusions and impermeable welding. Fitow electrode cap detection system

can meet the detection of surface defects in the working area of the welding electrode cap as well as

the detection of the round diameter of the end face.

Fitow electrode cap detection system is designed to detect surface defects in the working area of the welded electrode cap and the diameter of the end circle, using camera imaging for image management, automatic identification of the blade cut by analyzing the image data, and automatic storage of the image analysis data. This improves the quality of the weld and avoids potential quality risks; it increases the utilization of the electrode cap and saves material costs.

Project Overview

Through visual detection equipment equipped with algorithms, linked with welding robots, electrode cap grinding is completed, automatic defect detection and diameter detection, end face defect detection accuracy of 0.5mm*0.5mm, end face round diameter detection accuracy of 0.05mm, detection beat less than 1S/time, the whole process of equipment operation without manual participation, detection stability and consistency is much higher than the manual visual detection methods.

Solution

Detection defect source

Welding technology is used in many industrial sectors such as aerospace, automotive, shipbuilding, construction, and mechanical engineering. Spot welding technology is an indispensable process. Spot welding is a method of welding in which a welding joint is formed between the contact surfaces of two lapped workpieces using a columnar electrode. When spot welding, the workpiece is first pressurized to make close contact, then the current is switched on and the workpiece melts at the point of contact under the action of resistive heat, which forms a welded joint when it cools.

Advantages

The entire detection process is carried out without downtime to ensure production efficiency; it saves the factory a lot of money and time in the manual detection; the accuracy fully meets the highest quality standards of international automotive manufacturers; each detection data can be traced to enhance competitiveness.