Stamping Finished Parts Surface Inspection System

Stamping Finished Parts Surface

Inspection System

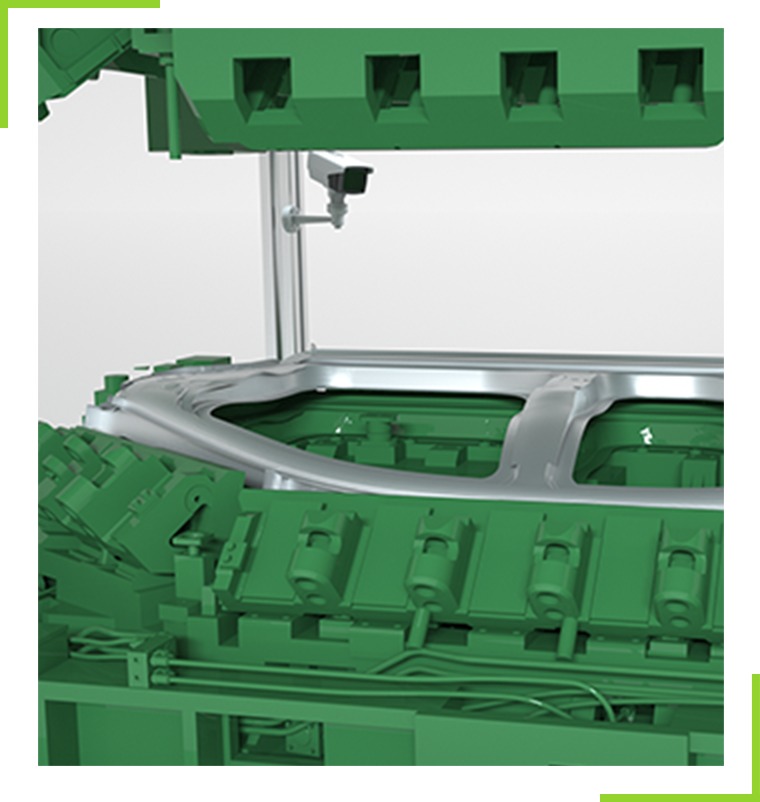

Full-Coverage and High-Precision Inspection for Maximum Body Dimensions

Rapid Detection of Finished Part Surface Defects

Full-Coverage and High-Precision Inspection for Maximum Body Dimensions

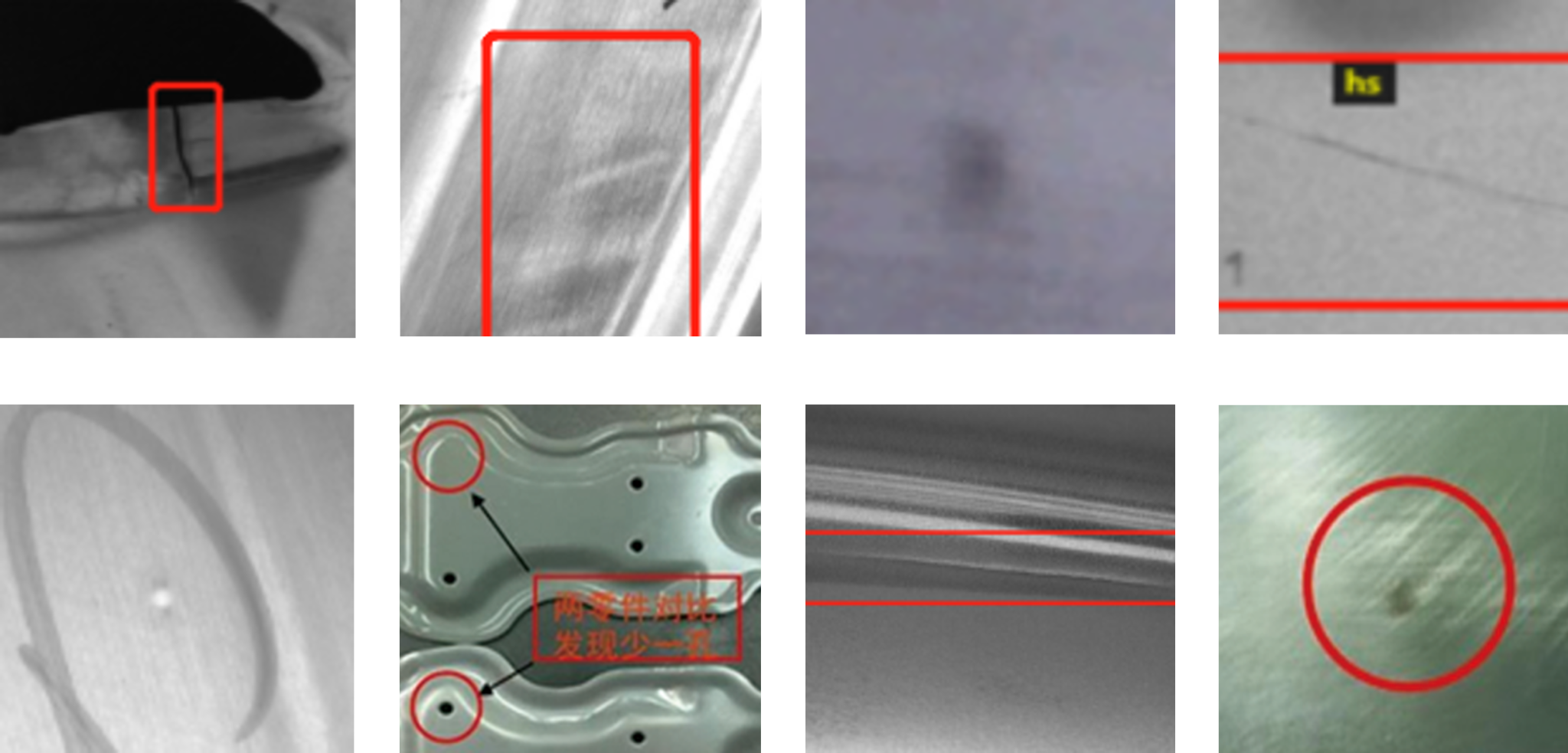

Rapid Detection of Finished Part Surface Defects

-

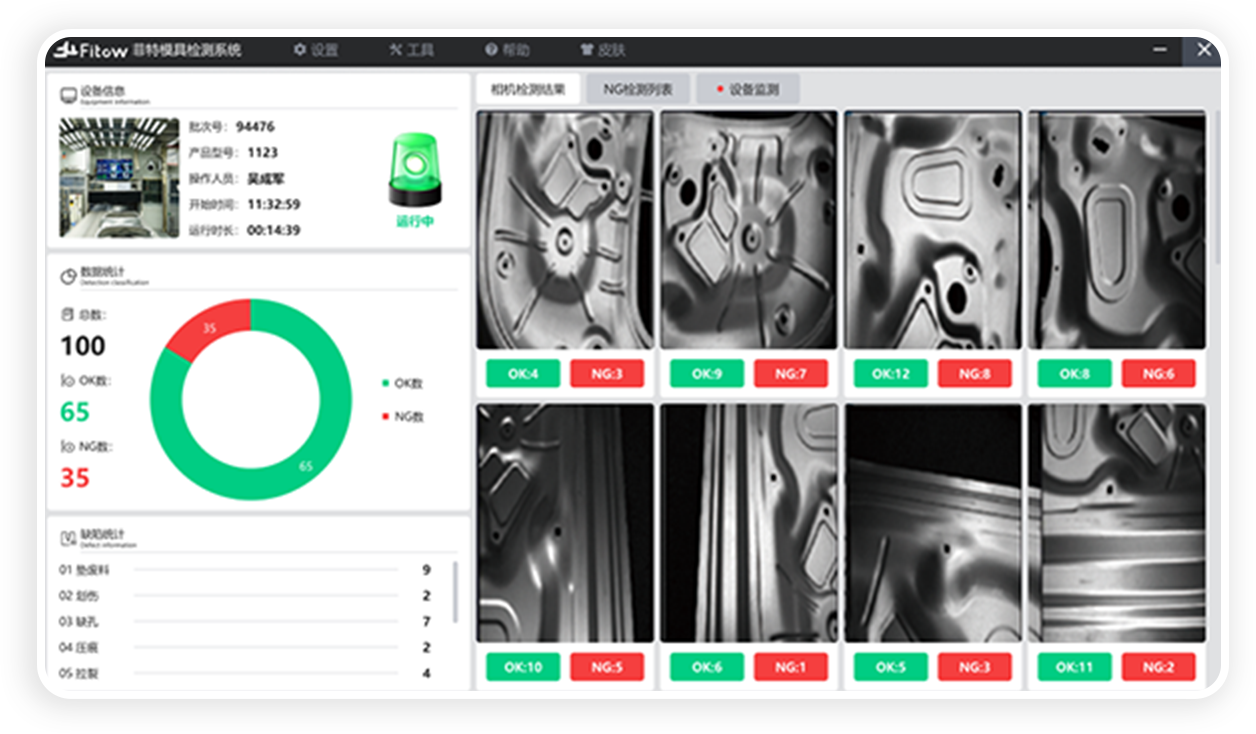

By combining a camera matrix with AI-based inspection, the system replaces manual visual inspection and enables 100% inspection of finished parts. This reduces instability caused by human inspection and standardizes inspection criteria, significantly lowering the risk of defective products leaving the production line.

-

Multi-angle camera matrix imaging enables more inspectionpositions and faster cycle timesCompatible with multiple types of stamped finished partsProduction line inspection data can be recorded and traced,providing data support for quality improvement

Multi-angle camera matrix imaging enables more inspectionpositions and faster cycle timesCompatible with multiple types of stamped finished partsProduction line inspection data can be recorded and traced,providing data support for quality improvement -

2mmInspection AccuracyInspection Cycle TimeConsistent with Production Line Cycle Time

CracksDents and ProtrusionsMissing HolesNeckingIndentation MarksWrinklesScrap ResidueScratches

CracksDents and ProtrusionsMissing HolesNeckingIndentation MarksWrinklesScrap ResidueScratches -

01.02.03.04.05.06.Real-time DetectionMultiple Cameras Combined with Shadowless LightingInterfaced with Production Systems and Press MachinesReal-time Viewing of Defect ImagesDefect Extraction for AI Algorithm ProcessingCan be integrated with robots to sort and removenon-conforming products

01.02.03.04.05.06.Real-time DetectionMultiple Cameras Combined with Shadowless LightingInterfaced with Production Systems and Press MachinesReal-time Viewing of Defect ImagesDefect Extraction for AI Algorithm ProcessingCan be integrated with robots to sort and removenon-conforming products

Technical Service

Quick Response

Full Tracking