One-Stop Algorithm Platform

One-Stop Algorithm Platform

Zero-Code Workstation

Zero-Code Workstation

End-to-End One-Stop Management

End-to-End One-Stop

Management

Cost Reduction and Efficiency Enhancement

Cost Reduction and

Efficiency Enhancement

A zero-code visual AI training platform that enables enterprises and non-professional algorithm users to easily complete AI model training—significantly lowering the barrier to adopting AI technologies.

The platform offers comprehensive, end-to-end AI image workflow management, covering project management, data management, data annotation, model management, model training, model testing, model deployment, and intelligent hardware device management.

The platform helps enterprises rapidly deploy AI-powered vision technologies, delivering efficient AI image algorithm solutions and accelerating the adoption of AI in industrial production.

Surface Defect Detection

Surface Defect Detection

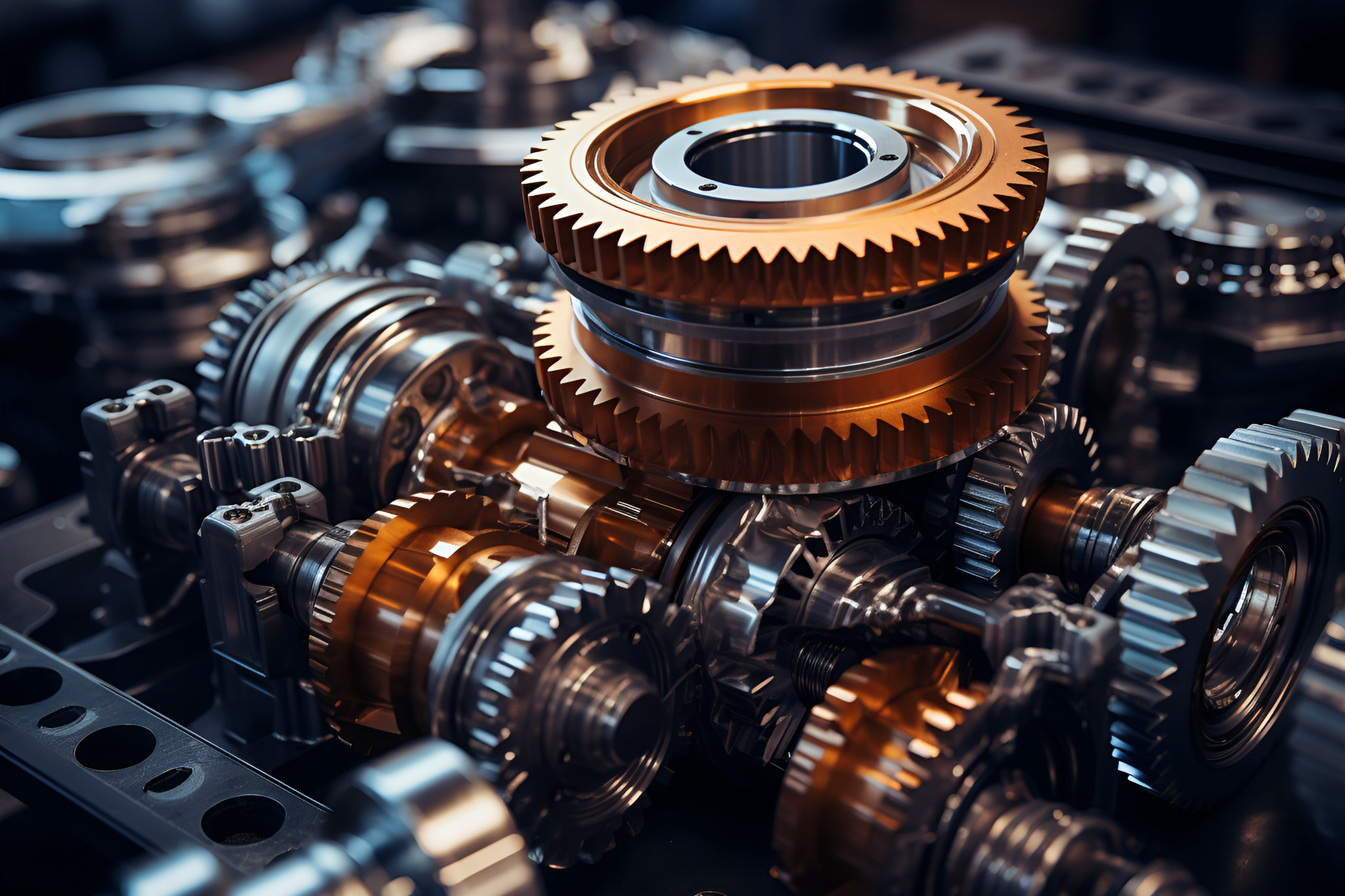

Designed for detecting surface defects or imperfections across various products, helping reduce quality inspection costs while improving inspection efficiency and accuracy.

Designed for detecting surface defects or imperfections across various products, helping reduce quality inspection costs while

improving inspection efficiency and accuracy.

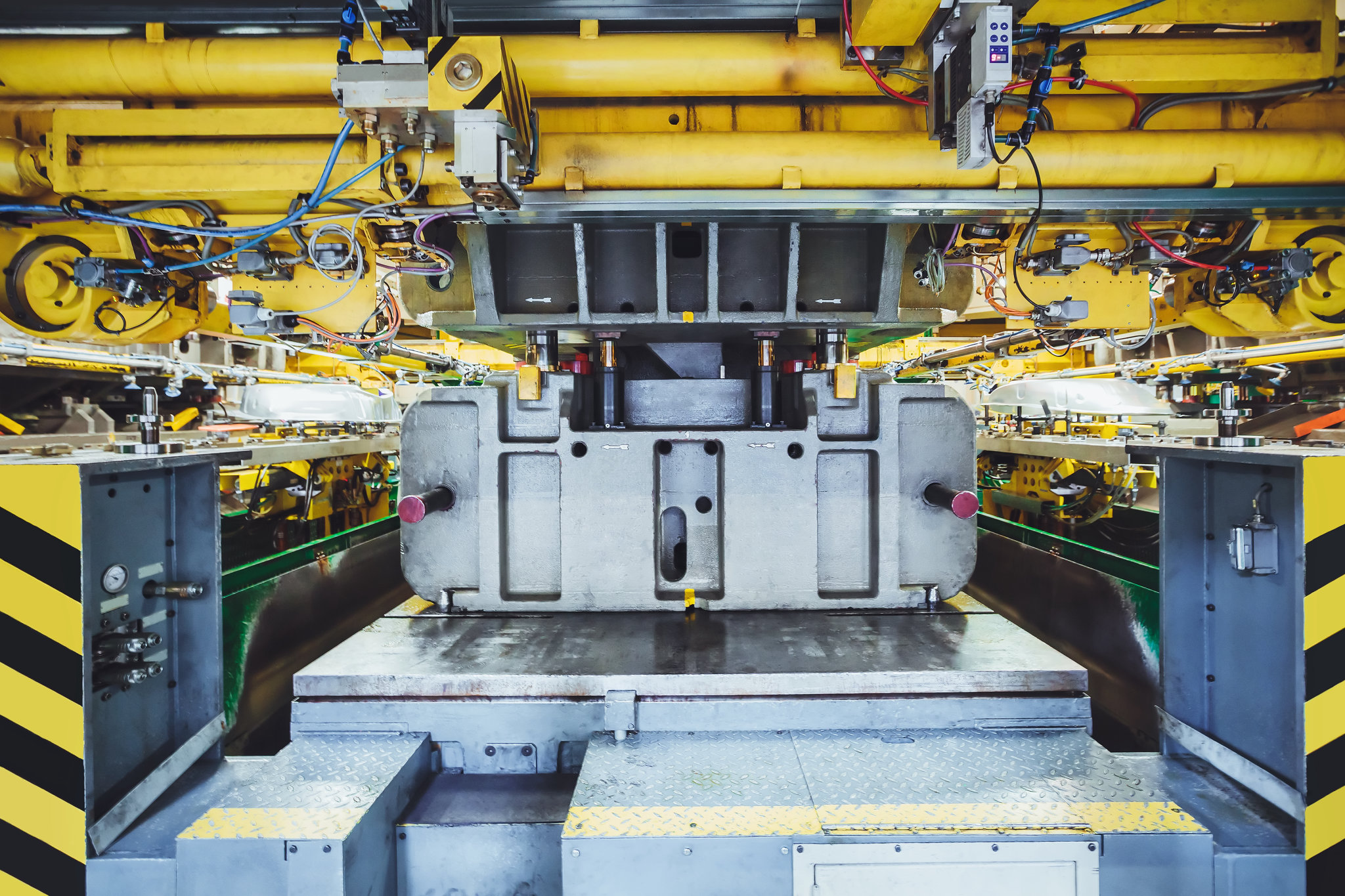

Stamped Product Defect Detection

Stamped Product Defect

Detection

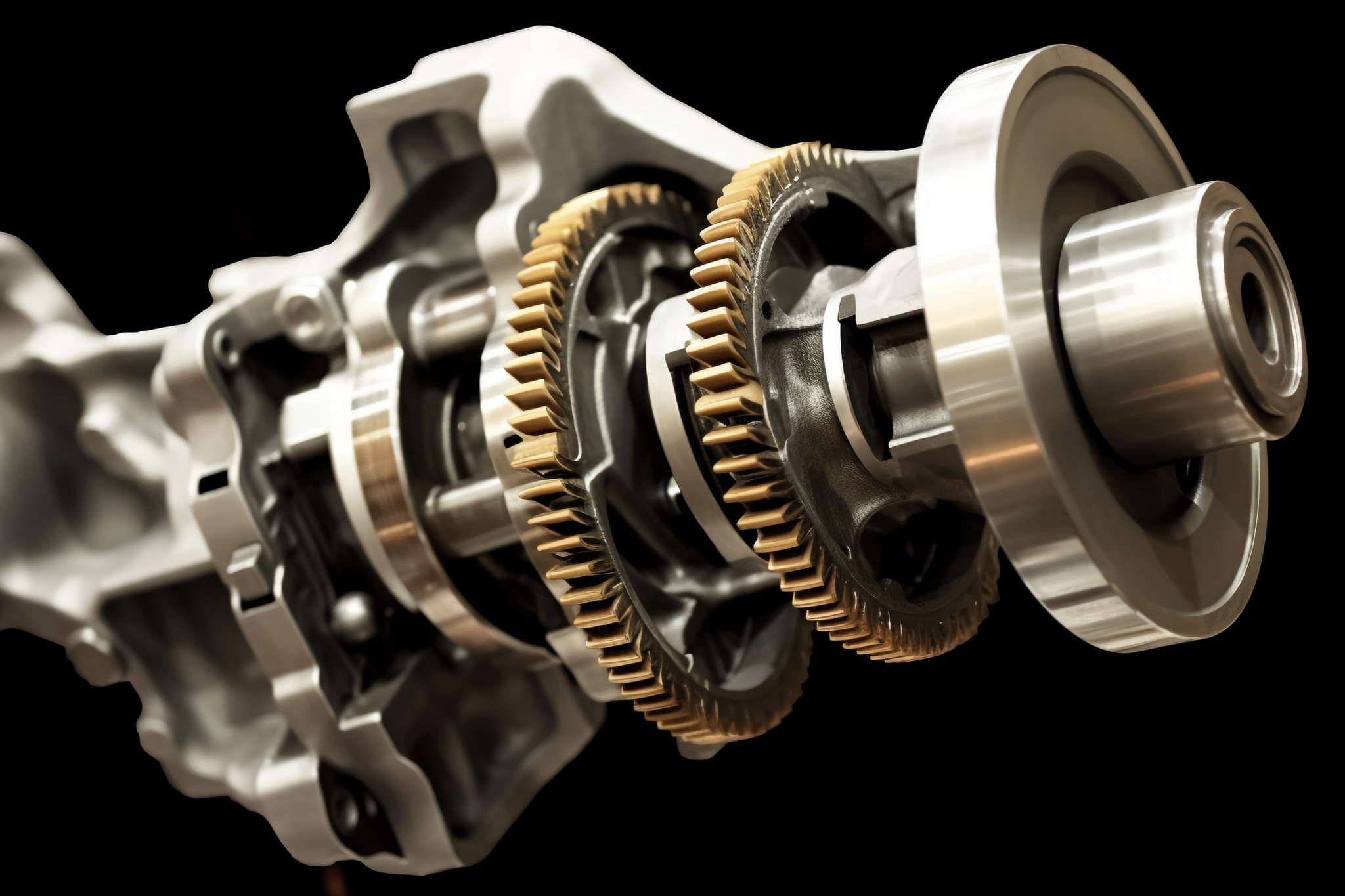

Crankshaft Defect Detection

Crankshaft Defect Detection

Automotive Wheel Hub Inspection

Automotive Wheel Hub Inspection

Missing Component Detection

Missing Component Detection

Pharmaceutical Inspection

Pharmaceutical Inspection

Internal Thread Burr Detection for Transmission Components

OCR Character Recognition

OCR Character Recognition

Designed for character detection and comparison across a wide range of products.

Designed for character detection and comparison across a wide range of products.

Rubbing Film Character Inspection

Rubbing Film Character

Inspection

Engine Block Character Inspection

Engine Block Character

Inspection

Batch Number Inspection

Batch Number Inspection

Vehicle VIN Recognition

Vehicle VIN Recognition

Three-Stage Inspection and Traceability

Three-Stage Inspection

and Traceability

One-Stop Algorithm Platform

One-Stop Algorithm Platform

Pre-trained Models for Industrial Applications

Pre-trained Models for Industrial Applications

Intelligent Hardware Management

Intelligent Hardware Management

Intelligent Label Filtering

Intelligent Label Filtering

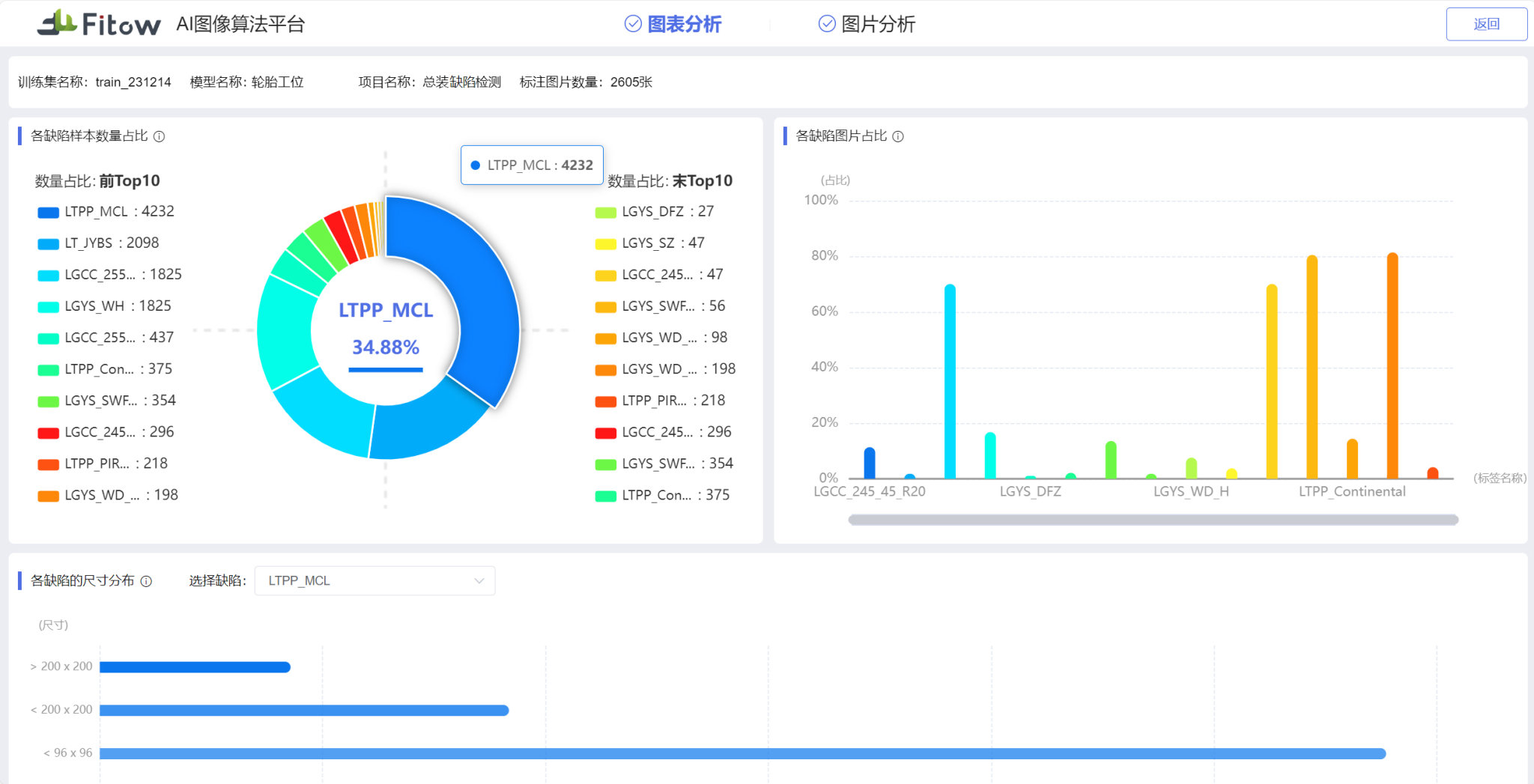

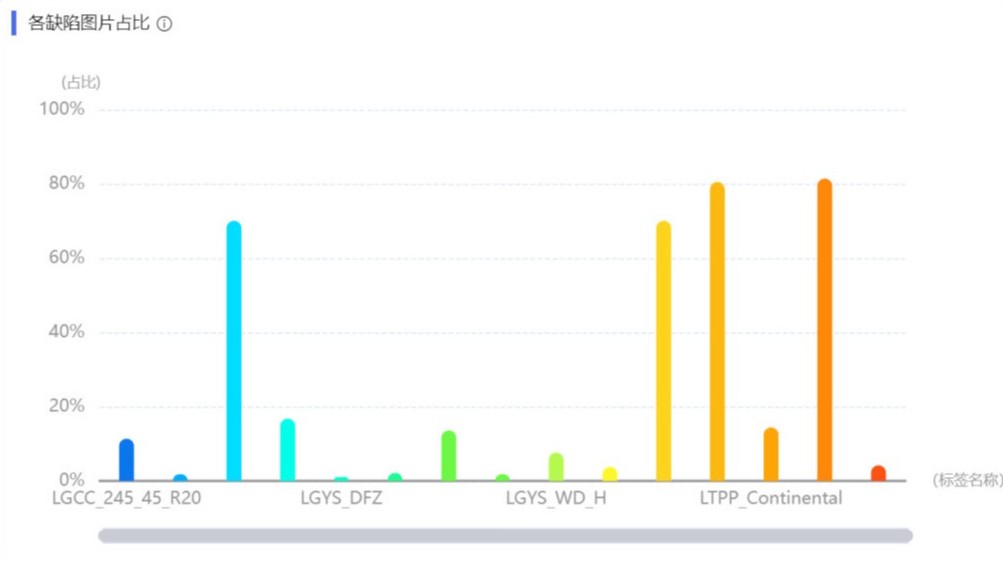

Clear Definition of Defect Scale

Clear Definition of Defect Scale

Intelligent Assisted Annotation

Intelligent Assisted Annotation

Leveraging Fitow’s years of data accumulation in industrial defect inspection scenarios, the platform offers pre-trained models suitable for a wide range of industrial defect detection tasks.

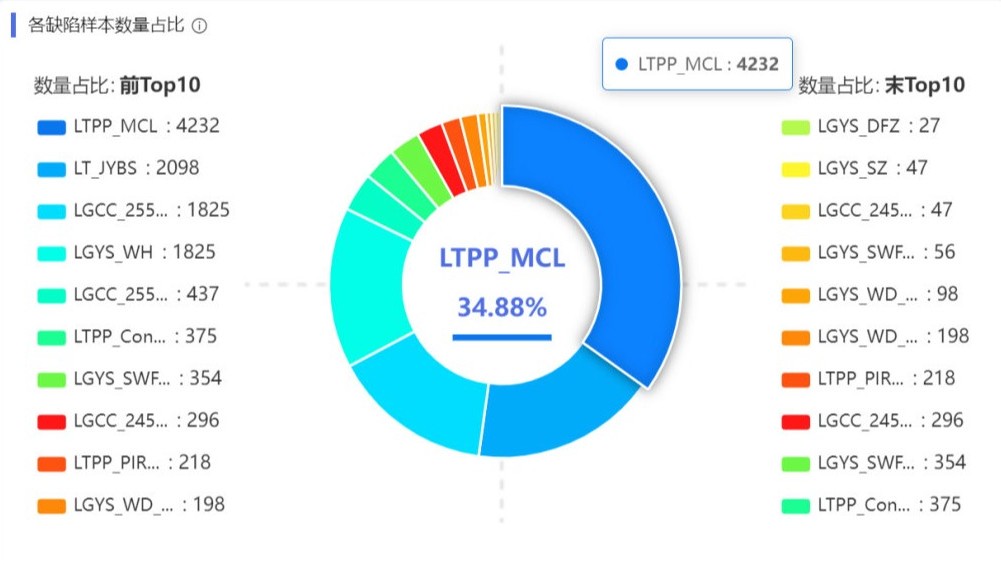

By utilizing object detection and instance segmentation models, the platform enables precise defect localization and multi-scale defect filtering.

The platform provides assisted annotation based on pre-trained models, automatically identifying and labeling targets within images—significantly improving annotation efficiency and reducing manual labor costs.

The platform supports intelligent label filtering by category, allowing users to screen annotated images efficiently, quickly identify and correct mislabeled data, and improve dataset quality and model training performance.

The platform supports the registration and operation of a full range of NVIDIA edge computing products, intelligent cameras, and edge computing devices. Through model deployment, it enables integrated edge–cloud applications for intelligent image processing.

Product Advantages

Product Advantages

-

The platform provides intelligent annotation services with support for result validation and manual correction, allowing users to quickly review and refine automatically generated annotations. This approach significantly accelerates the annotation process while ensuring high labeling accuracy and quality.

The platform provides intelligent annotation services with support for result validation and manual correction, allowing users to quickly review and refine automatically generated annotations. This approach significantly accelerates the annotation process while ensuring high labeling accuracy and quality. -

- Dataset

- Dataset

- Dataset

- Dataset

112233Training SetVersionTraining SetVersionTraining SetVersionThe platform provides comprehensive data management capabilities, enabling easy import of third-party datasets in COCO format. Within data management, users can create multiple folders under the same dataset and flexibly select subsets of data as training sets, allowing more efficient and organized data structuring.Each time a dataset is modified or updated, the platform automatically generates a new version and records detailed change logs and annotations, enabling full traceability of dataset evolution. This approach effectively addresses data drift across diverse application scenarios and supports precise AI model training. -

The platform supports intelligent image filtering by label category, allowing users to efficiently identify mislabeled data and quickly complete dataset cleaning—significantly improving data processing efficiency.

The platform supports intelligent image filtering by label category, allowing users to efficiently identify mislabeled data and quickly complete dataset cleaning—significantly improving data processing efficiency. -

The platform offers comprehensive data statistical analysis tools to help users thoroughly evaluate datasets before training begins. These analyses include label count statistics, class distribution analysis, annotation size distribution, and other multi-dimensional metrics—providing clear insights into data characteristics and distributions, and enabling effective dataset optimization to improve model accuracy and robustness.

The platform offers comprehensive data statistical analysis tools to help users thoroughly evaluate datasets before training begins. These analyses include label count statistics, class distribution analysis, annotation size distribution, and other multi-dimensional metrics—providing clear insights into data characteristics and distributions, and enabling effective dataset optimization to improve model accuracy and robustness. -

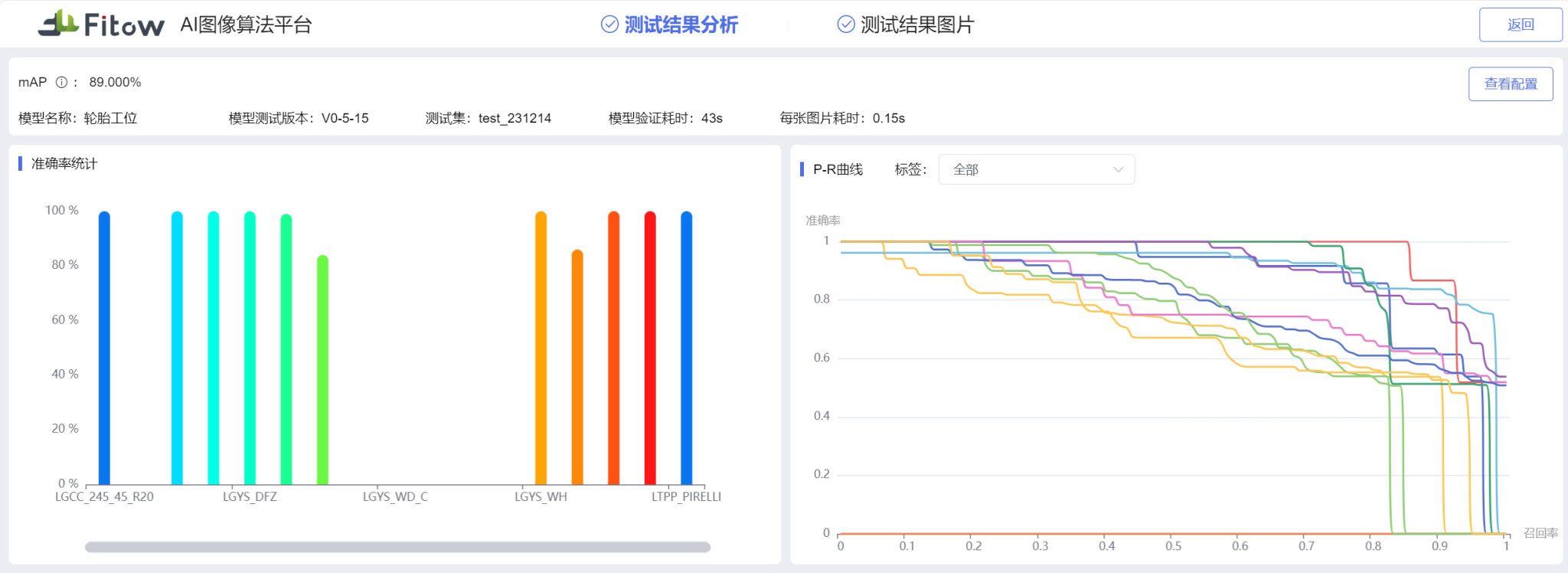

The platform enables real-time monitoring and evaluation of model training progress and performance. Users can view key metrics such as model accuracy, training time, iteration steps, training loss curves, validation PR curves, and confusion matrices, providing intuitive insights into model convergence and training effectiveness.

The platform enables real-time monitoring and evaluation of model training progress and performance. Users can view key metrics such as model accuracy, training time, iteration steps, training loss curves, validation PR curves, and confusion matrices, providing intuitive insights into model convergence and training effectiveness. -

The platform provides full lifecycle version management for critical AI assets, including datasets and models. It supports iterative optimization across multiple training versions, forming a closed-loop model iteration workflow while enabling efficient tracking and management of different model versions throughout production.

The platform provides full lifecycle version management for critical AI assets, including datasets and models. It supports iterative optimization across multiple training versions, forming a closed-loop model iteration workflow while enabling efficient tracking and management of different model versions throughout production.

Product Application Scenarios

Product Application Scenarios

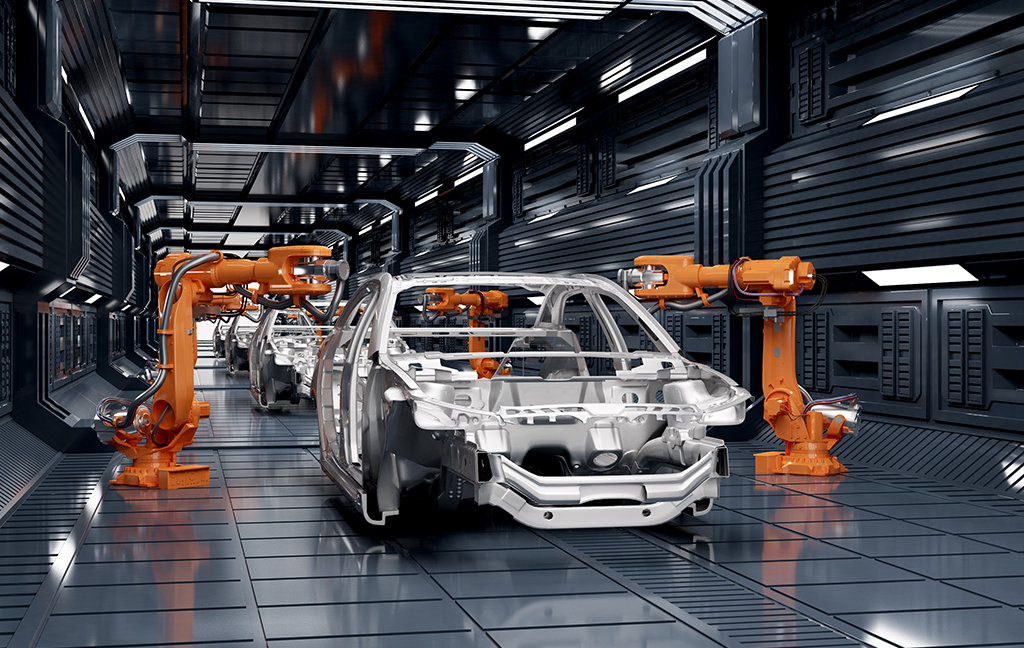

Automotive OEM

Automotive OEM

Automotive Components

Automotive Components

Pharmaceuticals

Pharmaceuticals

Chemical Fiber

Chemical Fiber

医药

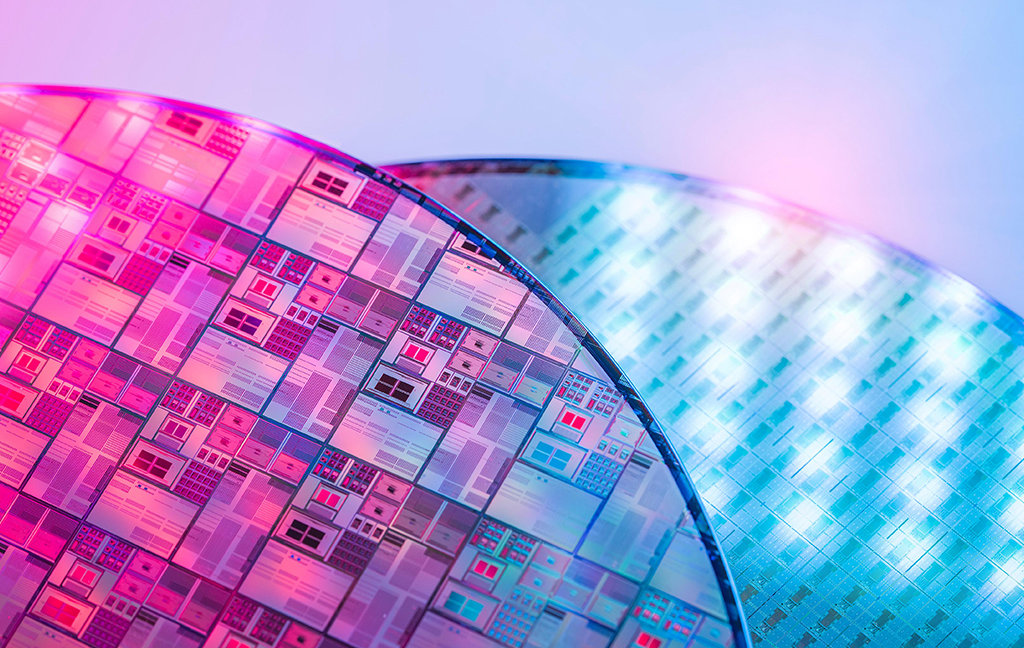

Semiconductors

Semiconductors

General Industrial

General Industrial