High Performance Self-developed Operator

High Performance Self-developed Operator

High Precision Structured Light Measurement Technology

High Precision Structured Light

Measurement Technology

3D Ultra Dynamic Fusion Technology

3D Ultra Dynamic Fusion Technology

Micron-level Defect Detection Technology for High Reflection Surface

Micron-level Defect Detection

Technology for High Reflection Surface

Multi-angle Optical Fusion Technology

Multi-angle Optical Fusion Technology

Optical Technology

Optical Technology

By utilizing the multi-angle optical fusion technology, the texture features of defects are highlighted from different angles, further improving the accuracy of detection algorithms. At the same time, the standardization of visual defects detection application solutions has also been formed, accelerating project implementation

Based on the principle of stripe reflection, it breaks through the industry challenges of low-cost and online micron level defect detection for high reflection surfaces of small caliber inner wall and multi curvature outer wall products

Self developed 3D cameras, developed visual guidance platforms, and utilized ultra dynamic fusion technology to achieve high reflection surface point cloud acquisition capabilities, accelerating the process of 3D projects, and improving efficiency to 130% of the original level

The self-developed line structured light measurement system is flexibly applied in high-precision measurement scenarios. By optimizing the calibration of the line structured light system, light plane calculation, and system noise reduction, dynamic online micron level repeatability measurement is achieved, with a repeatability accuracy of up to 5um

By accumulating experience in detection algorithms in different industries, we have independently developed nearly a hundred universal detection operators, mainly focusing on defects detection, image synthesis, 3D point cloud processing, measurement, and operator acceleration, saving nearly 30% of product delivery algorithm development time.

AI Technology

AI Technology

Breakthrough in Rare Data Generation Technology

Breakthrough in Rare Data

Generation Technology

Data Visualization Management and Mining System

Data Visualization Management

and Mining System

Large Scale distributed Training Capability

Large Scale distributed

Training Capability

Comprehensive Upgrade of Anomaly Detection Algorithm

Comprehensive Upgrade of

Anomaly Detection Algorithm

Memory-level High-Performance Algorithm Deployment Module

Memory-level High-Performance

Algorithm Deployment Module

Full Application of TRT Acceleration Technology

Full Application of TRT

Acceleration Technology

Fitow comprehensively conquered hardware acceleration technology and transformed all industrial specific AI algorithm models into TRT hardware acceleration, achieving nearly 100% speed improvement and reaching the industry's first tier level

Fitow has comprehensively upgraded the AI deployment module, starting with low-level optimization and delving into memory level management granularity, reducing the inference and communication time of the AI model to 30% of the original time

Fitow has continuously released the third version of the anomaly detection algorithm, which, when combined with his advanced optical imaging system, can achieve the same accuracy as traditional supervised learning algorithms and match the performance of the industry's SOTA algorithm

Large distributed clusters and independently developed efficient distributed training management systems, with the ability to quickly iterate models and pre train large models

A comprehensive data mining and management system that is more agile in perceiving data dimensions and changes, assisting in model evolution and iteration

In response to industry pain points, a methodology for rare data augmentation has been summarized and developed, integrating multiple rare data augmentation technologies. Now able to stably generate rare data to assist in the model training process

Software Interaction Technology

Software Interaction Technology

Agile Hybrid System Architecture Design

Agile Hybrid System Architecture Design

User-Friendly and Reliable Human–Machine Interaction Models

User-Friendly and Reliable

Human–Machine Interaction Models

Ultra-High-Speed Detection Engine

Ultra-High-Speed Detection Engine

Built upon integrated high-performance AI algorithm modules, the inspection engine enables ultra-high-speed scheduling and execution of algorithm models.

Built upon integrated high-performance AI algorithm modules,

the inspection engine enables ultra-high-speed scheduling and

execution of algorithm models.

The user interface design meets the needs of industrial production, incorporating intelligent interaction modes such as touchscreen interaction, voice alarms, and image recognition technologies, allowing users to operate and control the system more conveniently.

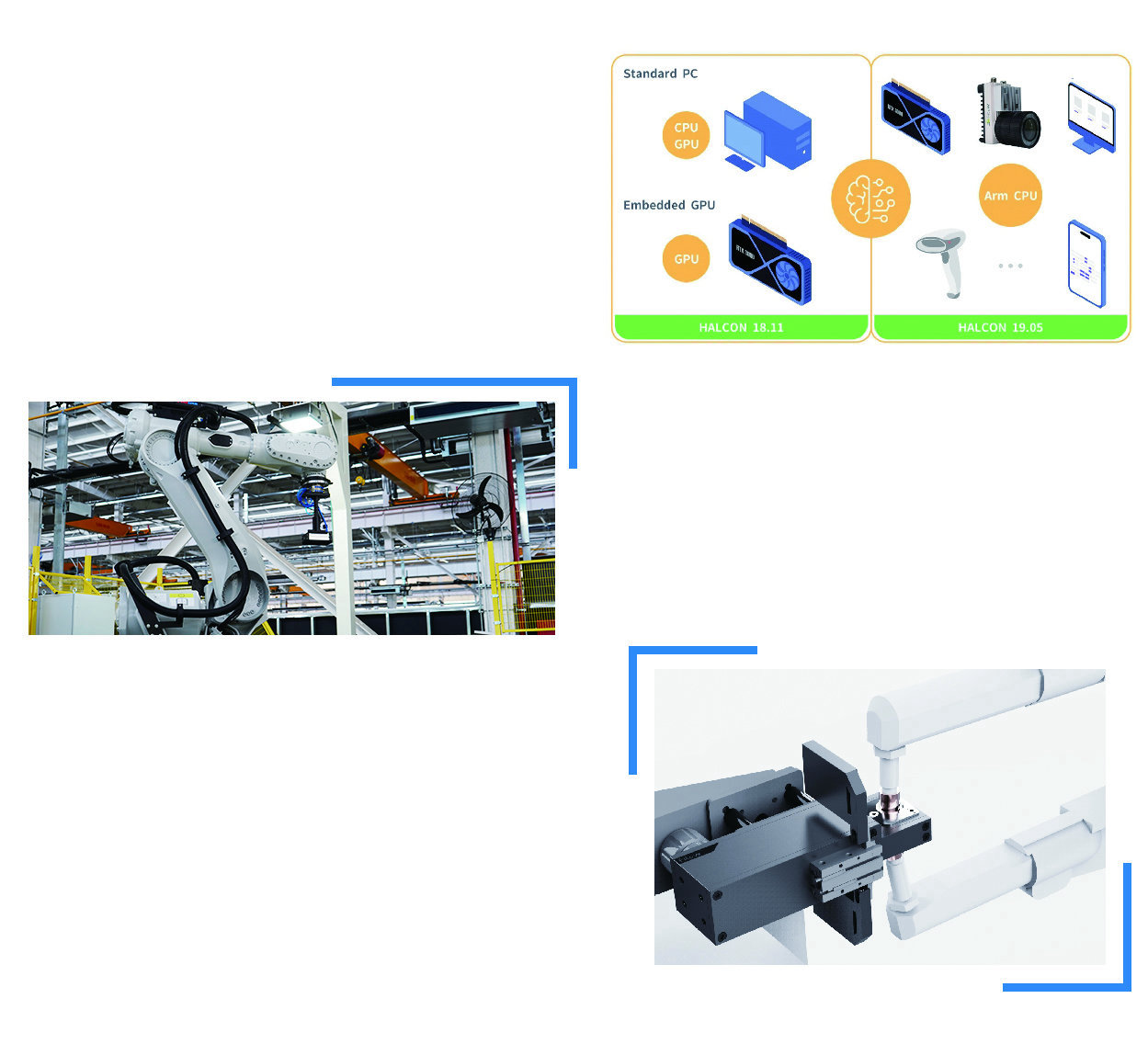

Designed to meet customers’ requirements for high-performance intelligent application scenarios, the architecture integrates built-in data analytics algorithms to enable statistical analysis of inspection data.

Hardware

Hardware

Embedded Algorithm Compression Deployment

Embedded Algorithm Compression Deployment

Calibration Technology for 3D Cameras and Robotic Arms

Calibration Technology for 3D Cameras and Robotic Arms

Edge Intelligence Hardware

Edge Intelligence Hardware

Fitow further quantified, distilled, and pruned the TRT acceleration model, achieving AI algorithm deployment on embedded GPU modules without losing detection accuracy, reducing computational power and hardware costs to 30% of the original level

In the fields of 3D point cloud processing, calibration, and robotic arm control, the Fitter hardware integrates multiple structured light modules, greatly improving the collection of point clouds in bright and dark surfaces

Highly integrates human-machine interaction platforms and AI image algorithm platforms, creating a closed loop of data acquisition, model training, algorithm iteration, and production application. (e.g., Smart Cameras, Edge Computing Boxes)

About Us

Product Center

Technology Platform

Contact Us