Decoiled Sheet Metal Quality Inspection

Decoiled Sheet Metal Quality Inspection

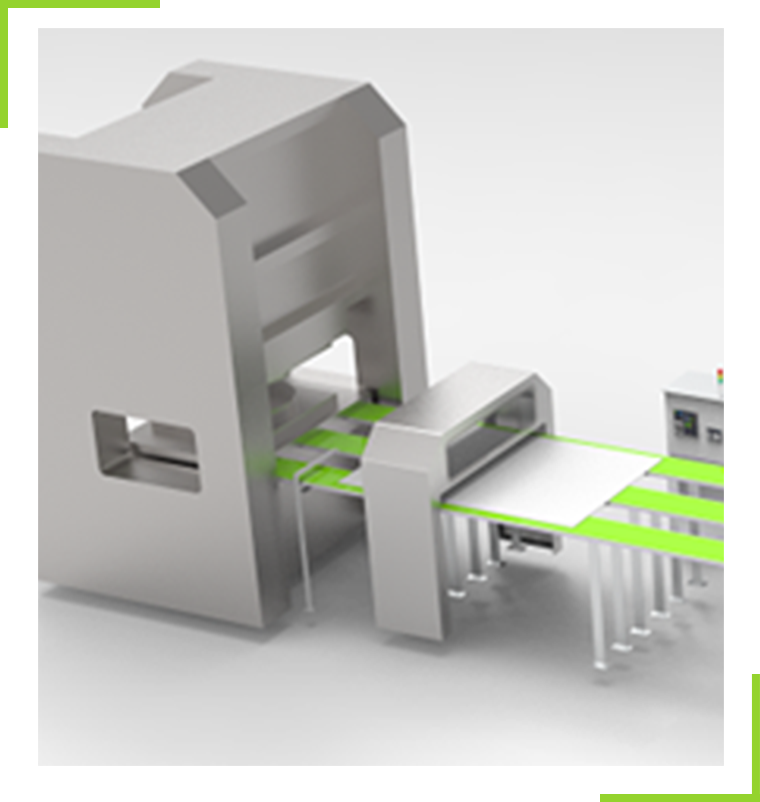

High-Precision Inline Inspection SystemDetection of Micro Surface Defects on Steel Sheets

High-Precision Inline Inspection System

Detection of Micro Surface Defects on Steel Sheets

-

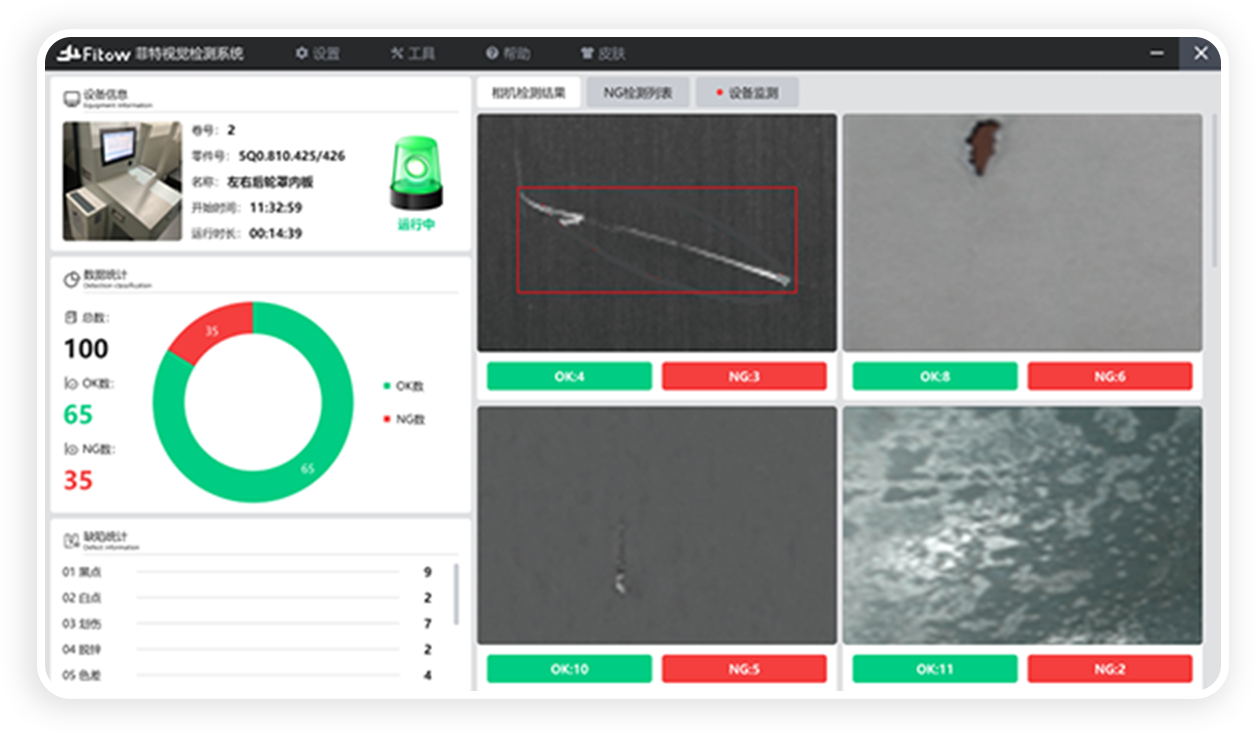

The decoiled sheet inspection system is used to detect various defects on steel sheets after decoiling. By replacing manual inspection with line-scan cameras and AI-based algorithms, the system improves product quality in subsequent stamping processes and avoids production cost losses caused by raw material defects. Detectable defects include black spots, scratches, transport damage, deep roll marks, color differences, and white spots, with an inspection accuracy of up to 2 mm.

-

Inspection data is traceableCompatible with multiple sheet material specificationsOnline operation without production line modificationCan be integrated with MES for production linkageAI-based defect recognition

Inspection data is traceableCompatible with multiple sheet material specificationsOnline operation without production line modificationCan be integrated with MES for production linkageAI-based defect recognition -

2mmInspection AccuracyInspection Cycle TimeConsistent with Production Line Cycle Time

Transport BruisingScratchesBlack DotRoller Imprint DepthColor Difference

Transport BruisingScratchesBlack DotRoller Imprint DepthColor Difference White Dot

White Dot -

01.02.03.04.Defect Information RecordingInformation TraceabilityViewing Detected Defect ImagesIntegration with MES System

01.02.03.04.Defect Information RecordingInformation TraceabilityViewing Detected Defect ImagesIntegration with MES System

Technical Service

Quick Response

Full Tracking