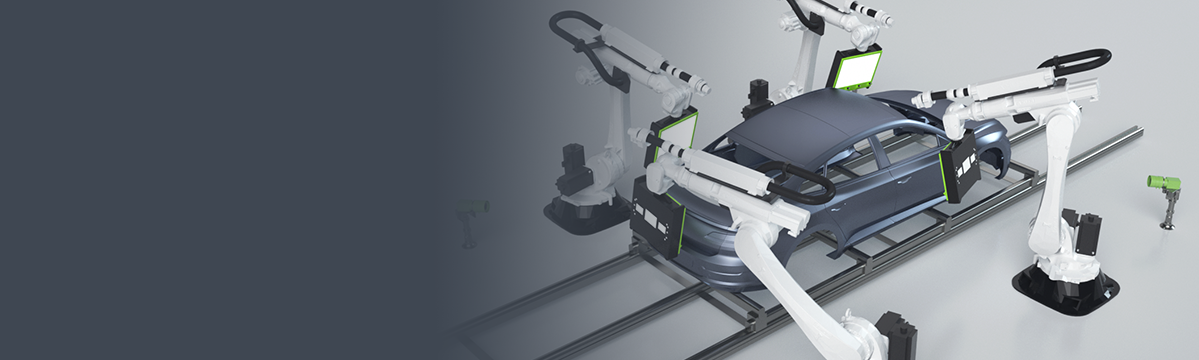

Paint Surface Defect Inspection System

Paint Surface Defect Inspection System

Leading Inspection Methods and Technologies

Overcoming Inspection Challenges of High-Gloss Paint Surface

AI algorithms enable fast and efficient model training, significantly improving inspection speed

Leading Inspection Methods and Technologies

Overcoming Inspection Challenges of High-Gloss Paint Surface

AI algorithms enable fast and efficient model training,

significantly improving inspection speed

-

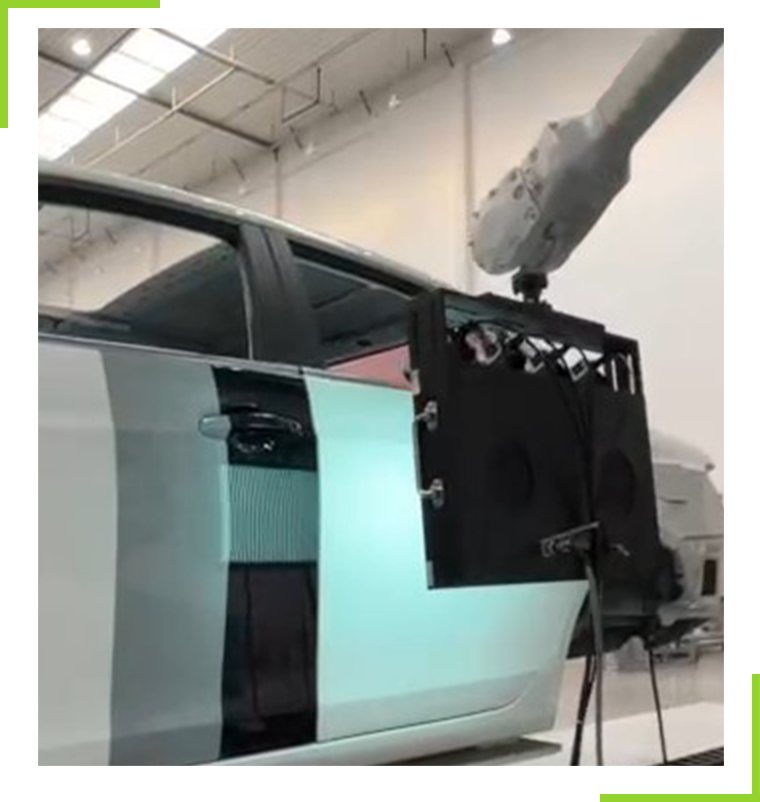

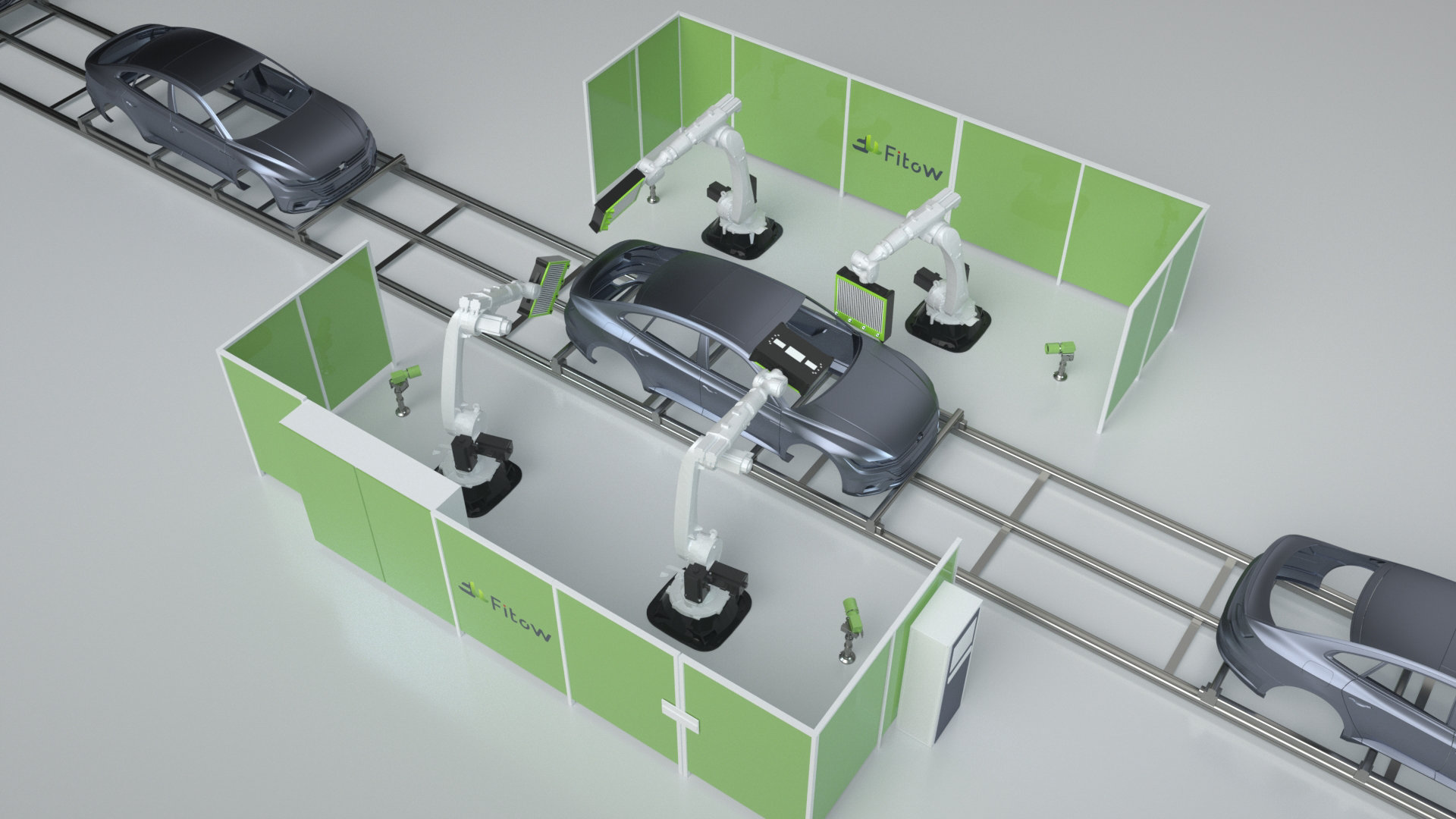

Designed for paint surface defect detection and precise localization in the Paint Shops and Final Assembly Shops of automotive OEMs.It effectively addresses issues such as missed detections and false inspections caused by visual fatigue from prolonged manual work under high-intensity lighting.The system generates individual inspection reports for every vehicle. The accumulated defect data serves as a powerful basis for decision-making in quality control and process optimization, significantly elevating the level of intelligent production management.

-

Supports full color range inspection, including two-tone body inspectionLow overall cost; lightweight image acquisition system enables the use oflower-payload robotic armsSupports both tracking and stop-and-go inspection modes with a compactfootprintNo hardware modification required for new vehicle models; automatically adapts to different body curvatures on the production lineMax: 60 JPH real-time online inspection, adaptable to different productiontakt times

Supports full color range inspection, including two-tone body inspectionLow overall cost; lightweight image acquisition system enables the use oflower-payload robotic armsSupports both tracking and stop-and-go inspection modes with a compactfootprintNo hardware modification required for new vehicle models; automatically adapts to different body curvatures on the production lineMax: 60 JPH real-time online inspection, adaptable to different productiontakt times -

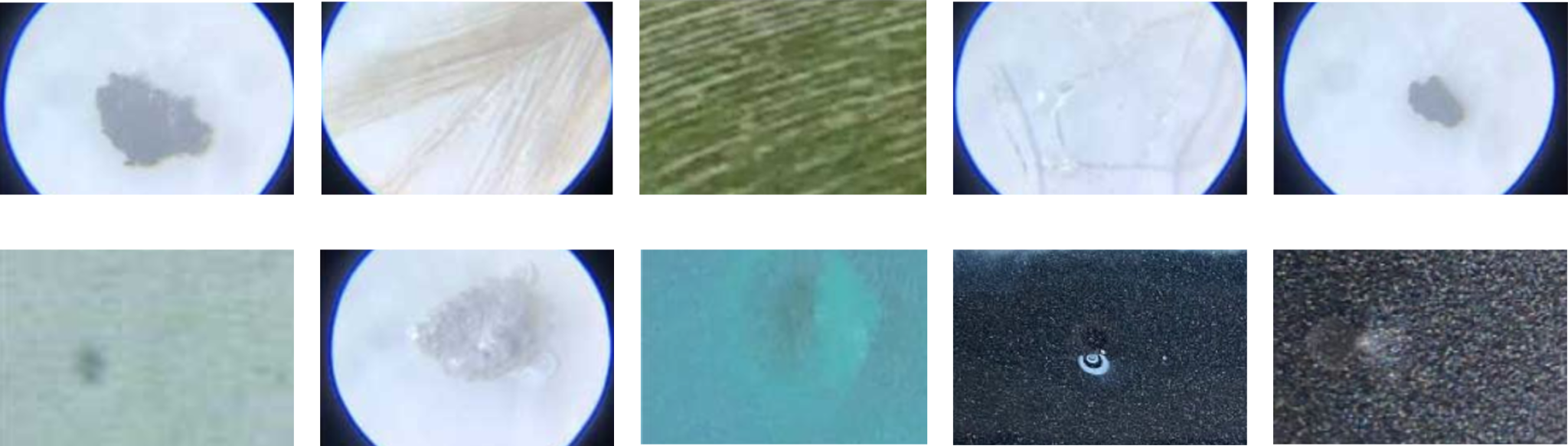

≥2mmDetectable Defect Types

Dust ParticlesOstrich FeathersScratchesFibersRust AshShrinkage HolesPaint ResiduePinholesSheet Metal DentsSheet Metal Bulges

Dust ParticlesOstrich FeathersScratchesFibersRust AshShrinkage HolesPaint ResiduePinholesSheet Metal DentsSheet Metal Bulges -

01、02、04、05、

Real-time online inspection synchronized with production takt time, no line stoppage required, ensuring high detection efficiency03、Provides comprehensive process data support by objectively recording inspection data and visualizing large-scale accumulated data to analyze defect root causes, enabling effective process optimizationMicron-level inspection enabled by high-resolution cameras, capable of consistently detecting defects smaller than the human visual thresholdHigh-precision defect localization with overall positioning accuracy within 3 mm, providing data interfaces for subsequent automated polishing and repair equipmentLifetime use: after a single machine learning process, no repeated training is required for new vehicle models, significantly reducing training costs

Real-time online inspection synchronized with production takt time, no line stoppage required, ensuring high detection efficiency03、Provides comprehensive process data support by objectively recording inspection data and visualizing large-scale accumulated data to analyze defect root causes, enabling effective process optimizationMicron-level inspection enabled by high-resolution cameras, capable of consistently detecting defects smaller than the human visual thresholdHigh-precision defect localization with overall positioning accuracy within 3 mm, providing data interfaces for subsequent automated polishing and repair equipmentLifetime use: after a single machine learning process, no repeated training is required for new vehicle models, significantly reducing training costs -

≤38℃No Conductive Dust5%-70%No CondensationAmbient Humidity0℃-35℃Electrical CabinetOperating TemperatureAmbient Temperature

-

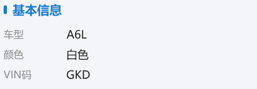

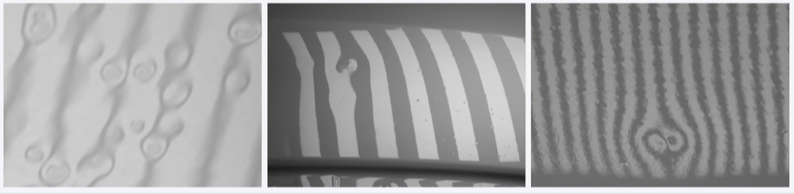

01.03.04.05.06.02.Region DefinitionVehicle 3D models can be segmentedinto customizable component regionswith user-defined namingRegion Level & Defect LevelDefect grades can be customized bycombining region levels with defectarea informationDefect DetailsClicking defect icons on the 3Dimage displays detailed informationincluding region level, size, and area3D Defect AnnotationDefect coordinates detected by AI algorithmsare digitally mirrored onto the 3D model, withdefect levels differentiated by customizablecolors for intuitive visualizationDefect Detection ImagesUsing horizontal stripe, vertical stripe, andwhite light inspection modes, the systemadapts to different body curvatures and detectsboth shape-related and shape-independentpaint surface defectsVehicle Model InformationIntegrates with existing OEM systemsto automatically retrieve vehicleinformation

01.03.04.05.06.02.Region DefinitionVehicle 3D models can be segmentedinto customizable component regionswith user-defined namingRegion Level & Defect LevelDefect grades can be customized bycombining region levels with defectarea informationDefect DetailsClicking defect icons on the 3Dimage displays detailed informationincluding region level, size, and area3D Defect AnnotationDefect coordinates detected by AI algorithmsare digitally mirrored onto the 3D model, withdefect levels differentiated by customizablecolors for intuitive visualizationDefect Detection ImagesUsing horizontal stripe, vertical stripe, andwhite light inspection modes, the systemadapts to different body curvatures and detectsboth shape-related and shape-independentpaint surface defectsVehicle Model InformationIntegrates with existing OEM systemsto automatically retrieve vehicleinformation

Technical Service

Quick Response

Full Tracking