Integrated Safety Control System

Integrated Safety Control System

Full Reuse of Existing Assets, Compatible with Existing Surveillance EquipmentProactive Early Warning and Device Reverse Control, Response Time < 0.3sDeep Learning with Recognition Accuracy up to 99.9%

Full Reuse of Existing Assets, Compatible with Existing Surveillance Equipment

Proactive Early Warning and Device Reverse Control, Response Time < 0.3s

Deep Learning with Recognition Accuracy up to 99.9%

Product Introduction

The Integrated Safety Control System is a monitoring and management system designed for production safety and personnel safety in factories and workshops. Through visual detection devices combined with proprietary algorithms, it comprehensively enhances the safety level of personnel, environment, and equipment from human-based prevention to technical prevention. It also supports AI action recognition to help improve assembly quality and reduce secondary inspection labor input.

Product Advantages

Full Asset Reuse

AI Empowerment, Compatible with Existing Surveillance Equipment

Supports Multiple Recognition Algorithms Such as Safety Helmet, Reflective Vest, Personnel Loitering, Off-Post, and Personnel Fall Detection

Full Area Coverage, Proactive Early Warning, and Device Reverse Control

Wide Field of View, Effectively Compensating for the Limitations of Photoelectric Gratings and Radar Occlusion

Algorithm Response Time < 0.3 Seconds

AI Recognition + Reverse Control to Control Equipment Before Accidents Occur

Deep Learning with High Accuracy

Based on Artificial Intelligence, Using Convolutional Neural Networks to Extract Image Features for Deep Learning

Recognition Accuracy > 99.9%

Stamping Production Line Safety Protection

Recognition Requirements

Identifies and Monitors On-Site Personnel Entering and Exiting the Stamping Production Line

Alarm Handling

Uses IoT Methods to Link with Equipment Startup and Combine with Recognition Results to Ensure Machines Do Not Operate When Personnel Are Present

Rolling and Open Mill Machine Safety Protection

When Hands (With or Without Gloves) or Operator Body Enter the Blue Zone, an Alarm Is Triggered Immediately; Entering the Red Zone Triggers Immediate Reverse Control to Stop the Equipment; Startup Is Not Allowed in Non-Running States.

Alarm Handling

1. Equipment in Stop State Cannot Be Started

2. Equipment in Running State Triggers Reverse Control to Stop

Recognition Requirements

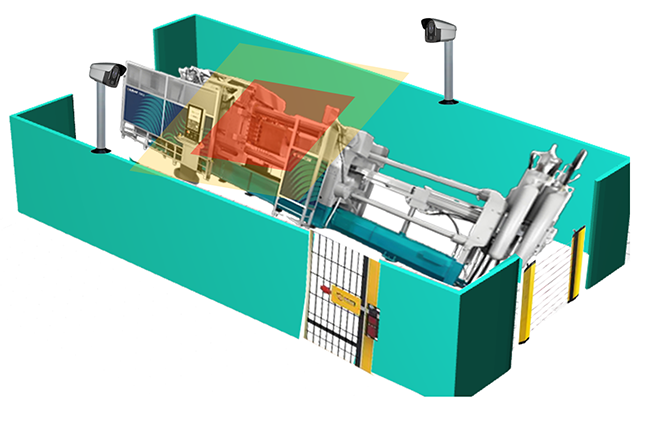

Die Casting Machine Safety Protection

Recognition Requirements

Restricts Personnel Access to Shadow Areas During Startup and Running States

Alarm Handling

During Startup and Running States, Voice Alerts Are Issued When Personnel Approach, and Reverse Control Stops the Equipment (PLC) Upon Entering the Warning Zone

Installation Principles

Install Close to Equipment, Height Requirements Cover the Largest Machine Models, Reusing Existing Safety Fences

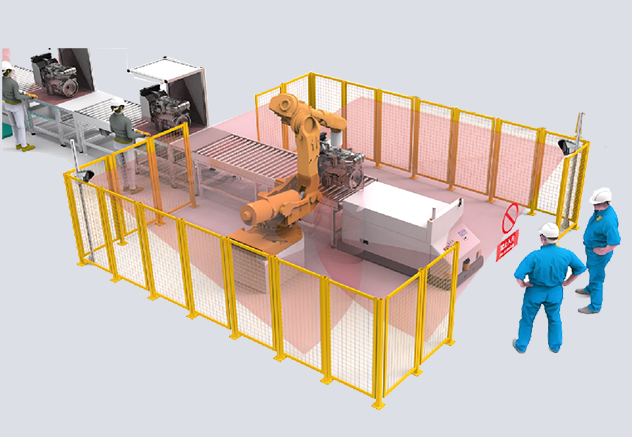

Processing Island Safety Protection

Recognition Requirements

When Operator Body Appears in the Warning Zone, an Alarm Is Triggered Immediately; Appearing in the Danger Zone Triggers Reverse Control to Stop the Equipment; Startup Is Not Allowed in Non-Running States

Alarm Handling

1. Equipment in Stop State Cannot Be Started

2. Equipment in Running State Triggers Reverse Control to Stop

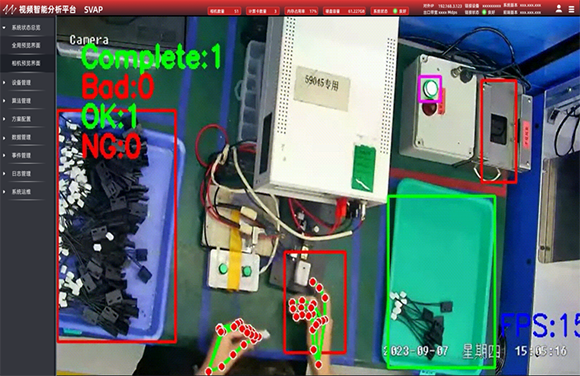

Action Recognition

Core Functions

Detects Personnel Status and Hand Movement Conditions

Determines Target Location and Type Through Visual Recognition, Generates Motion Trajectories Based on Target Tracking, and Analyzes Personnel Actions to Judge Completion

When Incorrect Actions Are Detected, the System Triggers Prompts via Screen Display and Alarm Light Flashing and Stores Associated Video in Real Time

The System Connects to Computers via Routers to Enable Visual Platform Display

Product Value

Full Asset Reuse

Compatible with Existing Surveillance Video and Supports Access to Different Brand Terminals.

Real-Time Early Warning with Rich Algorithms

7×24 Intelligent Video Analysis. Cloud-Edge Collaboration Delivers High Efficiency and Intelligence, with Alarm Latency < 0.3s, Effectively Addressing the Limitations of Manual Inspections.

Can Integrate with Existing Platforms or Operate Independently on Large Screens, Enabling Unified Data Aggregation and Breaking Data Silos for Easy Management.

Open, Flexible, and Easy to Manage

Technical Service

Quick Response

Full Tracking