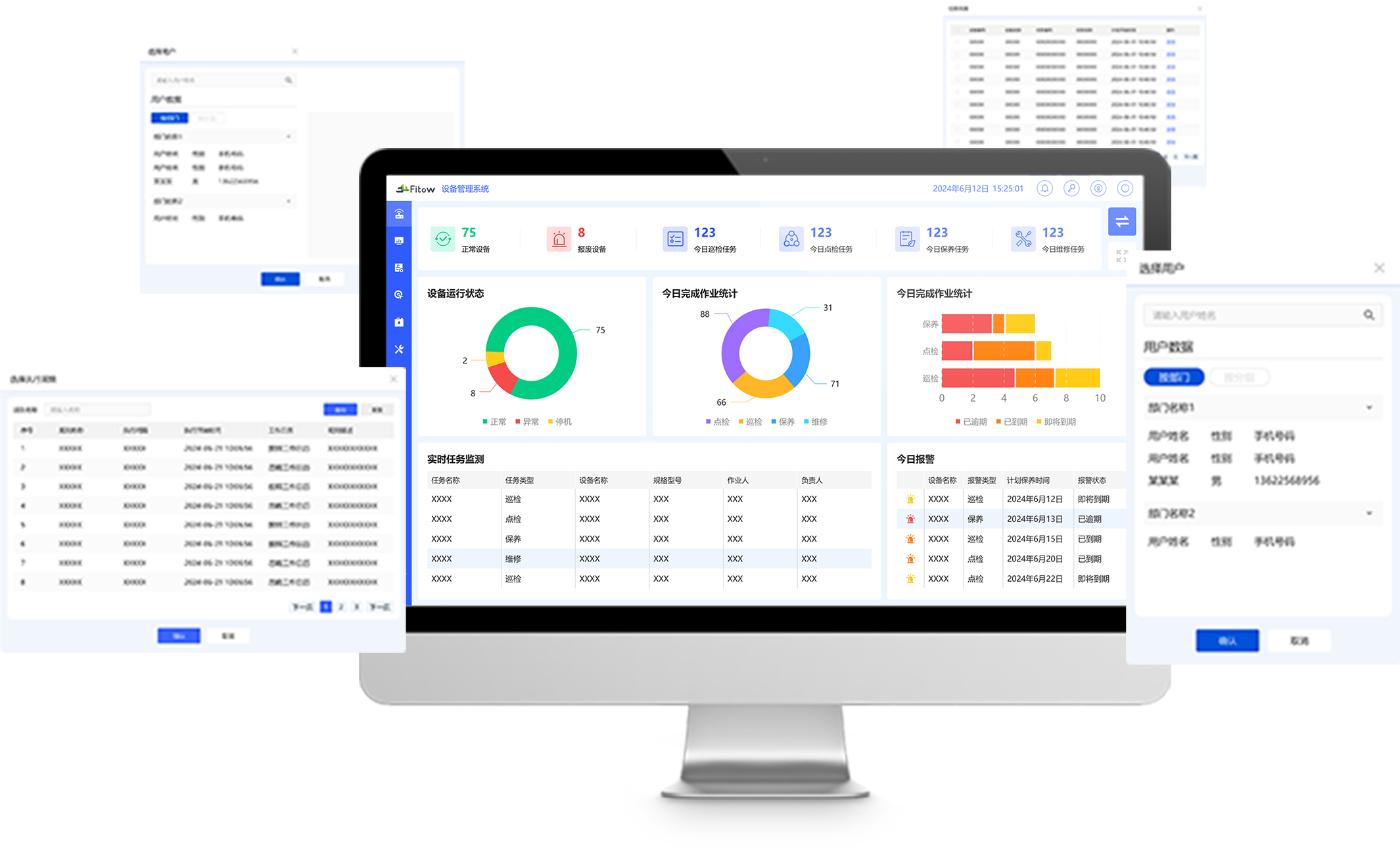

Intelligent Equipment Connectivity Management System

Intelligent Equipment Connectivity

Management System

Build a new digital collaborative management platform to make equipment management more transparent, simpler, and smarter

Build a new digital collaborative management platform to make equipment

management more transparent, simpler, and smarter

-

By leveraging cloud computing, IoT, visual analytics, and industrial AI models, existing enterprise data is refined to help improve equipment operation and maintenance efficiency, balance productivity among devices, and achieve comprehensive equipment lifecycle management.

By leveraging cloud computing, IoT, visual analytics, and industrial AI models, existing enterprise data is refined to help improve equipment operation and maintenance efficiency, balance productivity among devices, and achieve comprehensive equipment lifecycle management. -

Information ArchivingEquipment MonitoringSpare Parts ManagementAI-Assisted Decision MakingMulti-Terminal AccessIntegration and Compatibility

Information ArchivingEquipment MonitoringSpare Parts ManagementAI-Assisted Decision MakingMulti-Terminal AccessIntegration and Compatibility

Equipment ledgers with real-time archiving of inspection, patrol, repair, and maintenance information, enabling full lifecycle information traceabilityEnables large-screen real-time monitoring, overall equipment layout visualization, and abnormal risk alarmsApplies algorithm models to assist in processing equipment data and provide intelligent analytical decisionsSupports mobile terminal access with real-time equipment monitoring and alerts to meet real-time operation guidanceSeamlessly integrates with OA, ERP, ERP, MES, and other systemsSpare parts in/outbound query, information statistics, and scientific analysis of usage

Equipment ledgers with real-time archiving of inspection, patrol, repair, and maintenance information, enabling full lifecycle information traceabilityEnables large-screen real-time monitoring, overall equipment layout visualization, and abnormal risk alarmsApplies algorithm models to assist in processing equipment data and provide intelligent analytical decisionsSupports mobile terminal access with real-time equipment monitoring and alerts to meet real-time operation guidanceSeamlessly integrates with OA, ERP, ERP, MES, and other systemsSpare parts in/outbound query, information statistics, and scientific analysis of usage -

Basic Data ModelingInspection / Patrol ManagementMaintenance ManagementRepair ManagementSpare Parts ManagementEarly Warning ManagementKnowledge BaseMonitoring DashboardIntelligent Operations & MaintenanceThe equipment management system mainly includes thefollowing functions:

Basic Data ModelingInspection / Patrol ManagementMaintenance ManagementRepair ManagementSpare Parts ManagementEarly Warning ManagementKnowledge BaseMonitoring DashboardIntelligent Operations & MaintenanceThe equipment management system mainly includes thefollowing functions:

Adopts a modular design to flexibly adapt to enterprises of different scales and provide comprehensive and detailed management functions.

Adopts a modular design to flexibly adapt to enterprises of different scales and provide comprehensive and detailed management functions. -

工业制造行业

工业制造行业 For manufacturing enterprises with a large number of production equipment, the system monitors the operating status and production data of various machines on the production line in real time, promptly detects abnormalities, and avoids losses caused by equipment failures.Industrial Manufacturing Industry能源化工行业For enterprises such as power companies and petrochemical enterprises with critical equipment, the system enables remote monitoring and fault diagnosis to promptly detect and handle equipment failures, ensuring stable energy supply.

For manufacturing enterprises with a large number of production equipment, the system monitors the operating status and production data of various machines on the production line in real time, promptly detects abnormalities, and avoids losses caused by equipment failures.Industrial Manufacturing Industry能源化工行业For enterprises such as power companies and petrochemical enterprises with critical equipment, the system enables remote monitoring and fault diagnosis to promptly detect and handle equipment failures, ensuring stable energy supply. Energy and Chemical IndustryIn medical institutions and related biotech enterprises, full lifecycle tracking ensures compliant use and improves medical resource utilization efficiency. Regular calibration and maintenance reminders ensure stable performance and safe, reliable equipment.

Energy and Chemical IndustryIn medical institutions and related biotech enterprises, full lifecycle tracking ensures compliant use and improves medical resource utilization efficiency. Regular calibration and maintenance reminders ensure stable performance and safe, reliable equipment. Biopharmaceutical Industry公共设施行业Applied to urban public facilities, commercial property equipment, and retail store equipment. The system enables digital management of public facilities to ensure normal operation.

Biopharmaceutical Industry公共设施行业Applied to urban public facilities, commercial property equipment, and retail store equipment. The system enables digital management of public facilities to ensure normal operation. Public Facilities Industry

Public Facilities Industry -

Data-Driven Decision MakingMaintenance ManagementIntelligent AnalysisEnhance ReliabilityReduce CostsImprove EfficiencyBy monitoring equipment status in real time, predicting maintenance needs, reducing downtime, and optimizing operational processes, maintenance efficiency is significantly improved by 30–45%.Preventive maintenance reduces the frequency and cost of emergency repairs, extends equipment lifespan by 20–30%, and lowers overall operation and maintenance costs.Continuous monitoring of equipment performance enables timely identification and resolution of potential issues, ensuring stable operation and enhancing system reliability.Collects and analyzes equipment data to identify production blind spots, provide data support for enterprises, assist management in making more accurate decisions, and reduce spare parts inventory by 38%.Product Value

Data-Driven Decision MakingMaintenance ManagementIntelligent AnalysisEnhance ReliabilityReduce CostsImprove EfficiencyBy monitoring equipment status in real time, predicting maintenance needs, reducing downtime, and optimizing operational processes, maintenance efficiency is significantly improved by 30–45%.Preventive maintenance reduces the frequency and cost of emergency repairs, extends equipment lifespan by 20–30%, and lowers overall operation and maintenance costs.Continuous monitoring of equipment performance enables timely identification and resolution of potential issues, ensuring stable operation and enhancing system reliability.Collects and analyzes equipment data to identify production blind spots, provide data support for enterprises, assist management in making more accurate decisions, and reduce spare parts inventory by 38%.Product Value Allows managers to remotely monitor and control equipment, especially in remote areas or hazardous environments, improving management efficiency and safety, and reducing maintenance costs by 24–36%.Uses artificial intelligence and machine learning to analyze equipment data, scientifically predict equipment failures and performance degradation, provide trend warnings, and significantly reduce equipment failure rates by 18–28%.

Allows managers to remotely monitor and control equipment, especially in remote areas or hazardous environments, improving management efficiency and safety, and reducing maintenance costs by 24–36%.Uses artificial intelligence and machine learning to analyze equipment data, scientifically predict equipment failures and performance degradation, provide trend warnings, and significantly reduce equipment failure rates by 18–28%.

Technical Service

Quick Response

Full Tracking