Product Introduction

Production Safety Management

Digital Intelligence Platform

Equipment Management

AI Big Data Platform

Production Management

Comprehensive Solutions

Covers safety assurance for the five production elements: personnel, machines, materials, methods, and environment, enabling safety warnings such as behavior monitoring and location-based operations

Achieves comprehensive equipment information management, improves management efficiency and equipment utilization, and ensures optimal operating conditions and longer equipment lifespan

End-to-end monitoring and analysis of production data, flexible and agile with convenient deployment, enabling rapid information traceability and control management to support production

AI services including industrial data management, intelligent data mining, automated deployment, and visual presentation

Build comprehensive application services covering production, safety, development, AI big data, and equipment management

Fitow Industrial Digital Intelligence Platform

Fitow Industrial Digital

Intelligence Platform

Build a digital intelligence management platform and

empower enterprises with AI-driven digital production

Product Modules

Product Services

Application Results

Service Industries

Product Features

Product Introduction

Product Introduction

Leveraging cloud computing, IoT and other resources, and applying technologies such as big data, the Internet of Things, visual analytics, and industrial AI algorithm models, this platform integrates development platforms, big data platforms, equipment management, safety management, and visualization dashboards to comprehensively manage the entire enterprise production process. Through AI-based control and scientific optimization, it forms a high-performance digital factory intelligent manufacturing platform, helping enterprises successfully achieve digital management and business transformation.

Product Features

Product Features

Product Modules

Product Modules

-

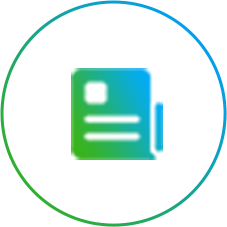

Transparent andEfficient ProductionIntelligent ProductionControlFocused on ProductionManagementAI ApplicationsCost Reduction andEfficiency ImprovementAchieveTools and MethodsDataLean ProductionIntelligent Decision-MakingCost Reduction and Efficiency ImprovementData AlgorithmsModules / Platforms

Transparent andEfficient ProductionIntelligent ProductionControlFocused on ProductionManagementAI ApplicationsCost Reduction andEfficiency ImprovementAchieveTools and MethodsDataLean ProductionIntelligent Decision-MakingCost Reduction and Efficiency ImprovementData AlgorithmsModules / Platforms

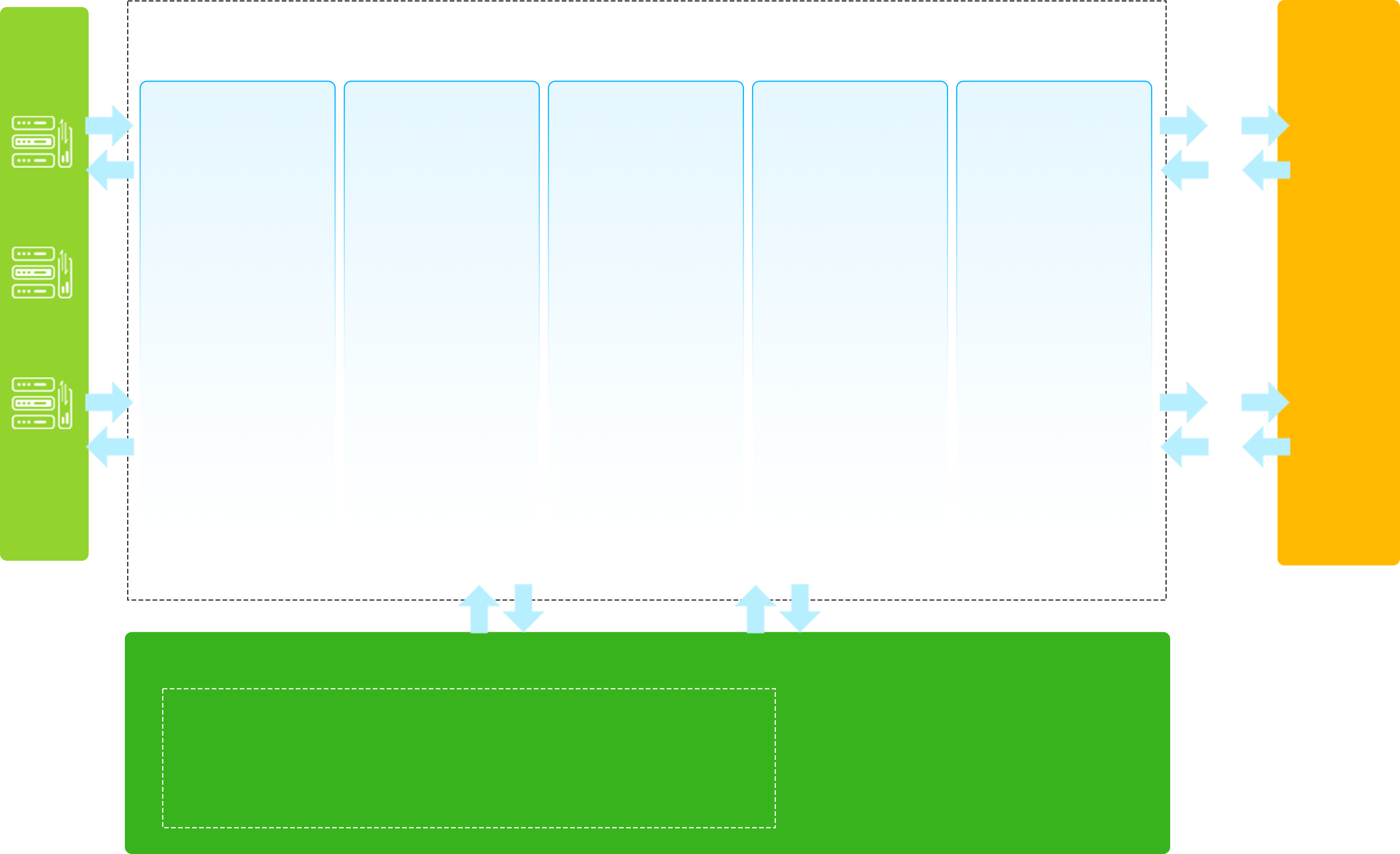

ComprehensiveVisualizationData FoundationData LayerIntelligent SchedulingProcess TrackingOperation PreventionEnergy ConsumptionOptimizationReduce Material StockFault PredictionReduce DowntimeData VisualizationQMSMESEquipment ManagementSystemWMSIndustrial ControlPlatformEMSRapid DeploymentPlatformComprehensive SolutionsWeb appSafety ManagementVisualization DashboardLarge ModelApplicationsPredictive MaintenanceData AnalysisVisual InspectionImage AlgorithmPlatformDigital TwinData GovernanceAI Data PlatformDigital Intelligence PlatformIndustrial SystemsBusiness DataProduction DataWarehouse DataInspection DataSystem-Reported DataLogistics DataOther DataCentered on customer needs such as production control, equipment management, quality optimization, supply chain services, and digital collaboration, providing industrial enterprises with one-stop solutions from data access and data analysis to top-level applications, targeting enterprises undergoing digital transformation in the industrial sector and those requiring comprehensive industrial digitalization.Reduce labor costs and enhance data analysis efficiency by connecting databases and computing resourcesUse proprietary technologies to connect the underlying architecture

ComprehensiveVisualizationData FoundationData LayerIntelligent SchedulingProcess TrackingOperation PreventionEnergy ConsumptionOptimizationReduce Material StockFault PredictionReduce DowntimeData VisualizationQMSMESEquipment ManagementSystemWMSIndustrial ControlPlatformEMSRapid DeploymentPlatformComprehensive SolutionsWeb appSafety ManagementVisualization DashboardLarge ModelApplicationsPredictive MaintenanceData AnalysisVisual InspectionImage AlgorithmPlatformDigital TwinData GovernanceAI Data PlatformDigital Intelligence PlatformIndustrial SystemsBusiness DataProduction DataWarehouse DataInspection DataSystem-Reported DataLogistics DataOther DataCentered on customer needs such as production control, equipment management, quality optimization, supply chain services, and digital collaboration, providing industrial enterprises with one-stop solutions from data access and data analysis to top-level applications, targeting enterprises undergoing digital transformation in the industrial sector and those requiring comprehensive industrial digitalization.Reduce labor costs and enhance data analysis efficiency by connecting databases and computing resourcesUse proprietary technologies to connect the underlying architecture -

Data Source ConnectionAI Data Modeling and Data MiningData ETL ProcessingData Service Publishing and Dashboard Display

Data Source ConnectionAI Data Modeling and Data MiningData ETL ProcessingData Service Publishing and Dashboard Display

Business Data AccessETL Data PreprocessingData Visualization Display

Business Data AccessETL Data PreprocessingData Visualization Display By applying AI big data technologies to real-time monitoring and analysis of production data, upstream and downstream production management needs are generated. On one hand, it extends supplier raw material quality control; on the other hand, it manages the full lifecycle of production and monitors production operations in real time to strengthen management.For developers and technical personnel engaged in data analysis and model training, it provides a one-stop experience including data import, model training, data governance, and online statistical visualization.Can be applied to Fitow vertical industry tasks, with models empowering enterprise production management.Machine Learning and Deep Learning Model AnalysisData Feature Engineering and Basic Information AnalysisSupports access to multiple database types such as MySQL, MS SQL Server, PostgreSQL, DB2, and SQLiteIncludes operators for machine learning, statistical analysis, and deep learning. Supports drag-and-drop layouts and flow-based model constructionSupports various data extraction, cleaning, transformation, slicing, and normalization tasksSupports rich chart component styling, custom dashboard layout arrangement, and built-in multiple dashboard templates

By applying AI big data technologies to real-time monitoring and analysis of production data, upstream and downstream production management needs are generated. On one hand, it extends supplier raw material quality control; on the other hand, it manages the full lifecycle of production and monitors production operations in real time to strengthen management.For developers and technical personnel engaged in data analysis and model training, it provides a one-stop experience including data import, model training, data governance, and online statistical visualization.Can be applied to Fitow vertical industry tasks, with models empowering enterprise production management.Machine Learning and Deep Learning Model AnalysisData Feature Engineering and Basic Information AnalysisSupports access to multiple database types such as MySQL, MS SQL Server, PostgreSQL, DB2, and SQLiteIncludes operators for machine learning, statistical analysis, and deep learning. Supports drag-and-drop layouts and flow-based model constructionSupports various data extraction, cleaning, transformation, slicing, and normalization tasksSupports rich chart component styling, custom dashboard layout arrangement, and built-in multiple dashboard templates -

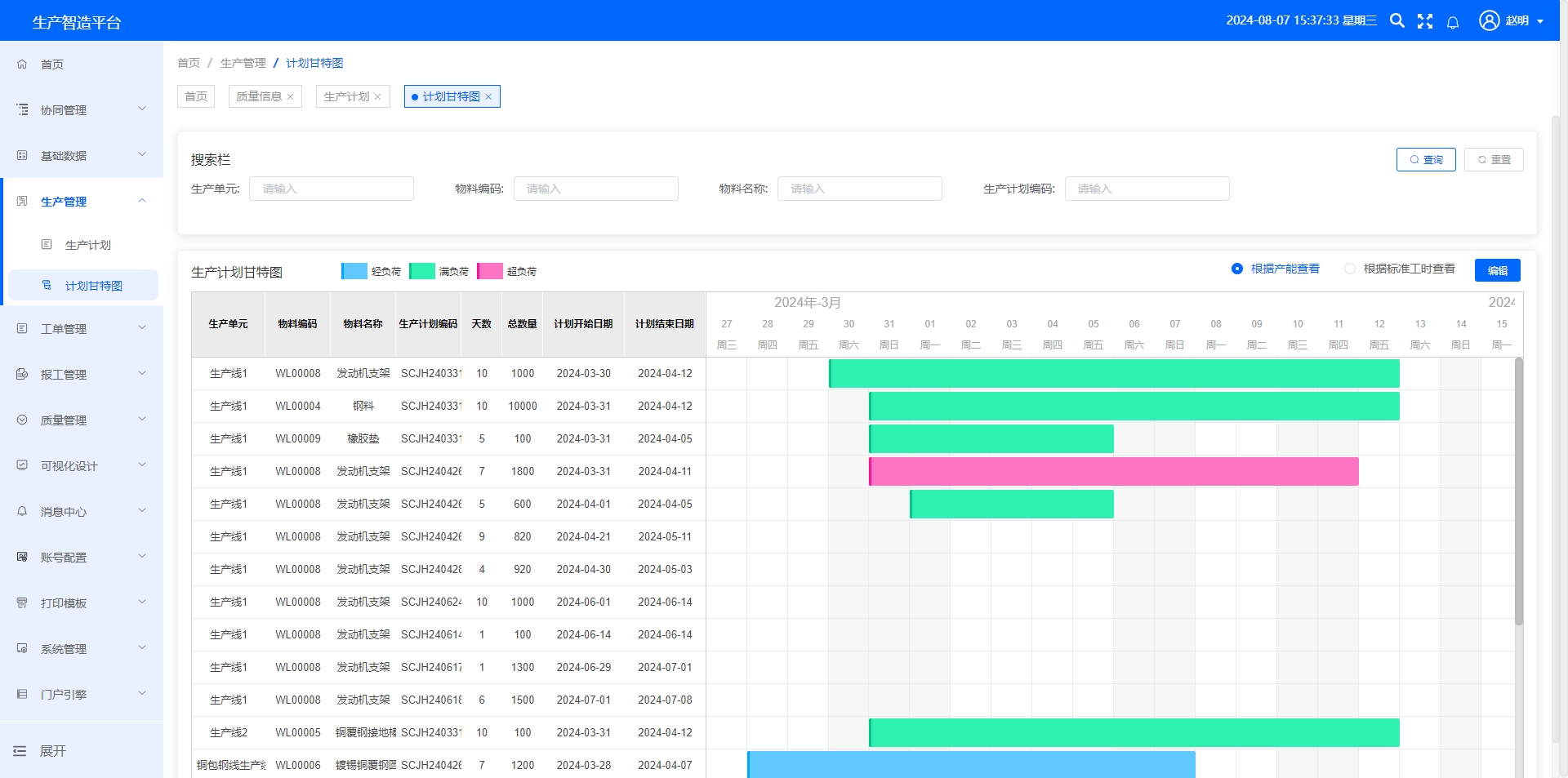

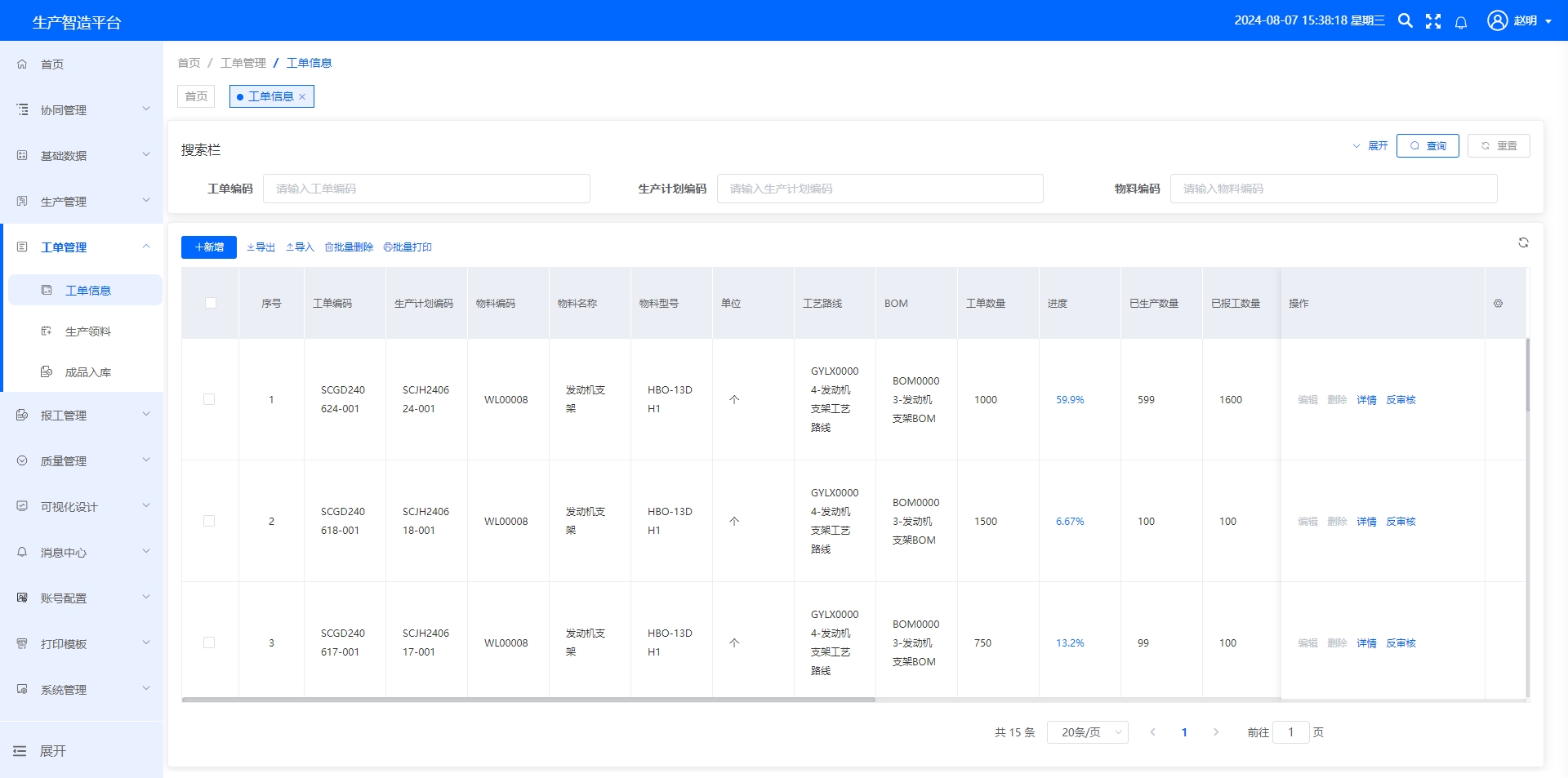

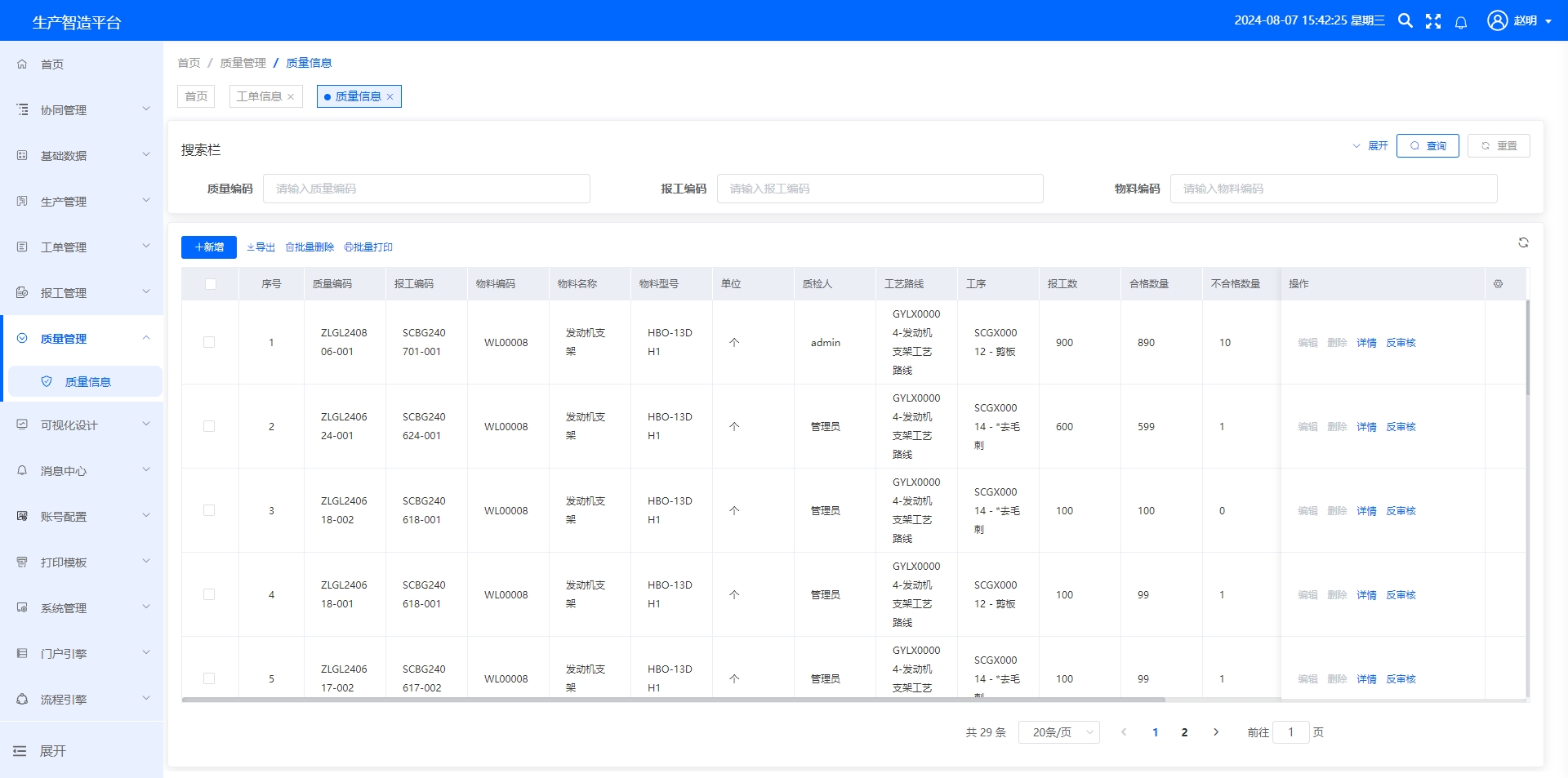

Production Planning and SchedulingProduction Quality ManagementProduction Work Orders and ReportingServes manufacturing enterprises by monitoring and analyzing the entire process including material distribution, warehousing, production planning, execution status, equipment status, production reporting, quality management, process guidance, dashboards, and finished goods outbound status, achieving information traceability and control management.For manufacturing enterprises, the MES system provides full-process traceability covering material distribution, warehousing, production planning, equipment status, production reporting, quality management, process guidance, dashboards, and finished goods outbound status.Helps enterprises optimize production plans, achieve optimal utilization of production resources, improve efficiency, and ensure delivery cyclesOne-click release of production plans with full-process tracking of work order progress, enabling seamless production processesEfficient quality supervision throughout the production process, avoiding quality issues and providing strong support for high-quality production

Production Planning and SchedulingProduction Quality ManagementProduction Work Orders and ReportingServes manufacturing enterprises by monitoring and analyzing the entire process including material distribution, warehousing, production planning, execution status, equipment status, production reporting, quality management, process guidance, dashboards, and finished goods outbound status, achieving information traceability and control management.For manufacturing enterprises, the MES system provides full-process traceability covering material distribution, warehousing, production planning, equipment status, production reporting, quality management, process guidance, dashboards, and finished goods outbound status.Helps enterprises optimize production plans, achieve optimal utilization of production resources, improve efficiency, and ensure delivery cyclesOne-click release of production plans with full-process tracking of work order progress, enabling seamless production processesEfficient quality supervision throughout the production process, avoiding quality issues and providing strong support for high-quality production -

Comprehensive Quality Management 4M1E

Comprehensive Quality Management 4M1E

Open Flame andSmoke Detection

Open Flame andSmoke Detection

Crowd DensityDetectionSmall AnimalDetectionPassenger FlowStatisticsLoitering DetectionFace RecognitionSafety HelmetDetectionWorkwear DetectionLong-Sleeve DetectionReflective VestDetectionLicense PlateRecognitionVehicle No-ParkingDetectionArea IntrusionDetectionLine-CrossingDetectionOn-Duty SleepingDetectionOff-Post DetectionSmoking and Phone-Calling DetectionFence-ClimbingDetectionFighting DetectionPerson Fall DetectionWeb FrontendHDMI

Crowd DensityDetectionSmall AnimalDetectionPassenger FlowStatisticsLoitering DetectionFace RecognitionSafety HelmetDetectionWorkwear DetectionLong-Sleeve DetectionReflective VestDetectionLicense PlateRecognitionVehicle No-ParkingDetectionArea IntrusionDetectionLine-CrossingDetectionOn-Duty SleepingDetectionOff-Post DetectionSmoking and Phone-Calling DetectionFence-ClimbingDetectionFighting DetectionPerson Fall DetectionWeb FrontendHDMI 全面质量管理4M1EAI Large Model ApplicationsFeaturesFlexibleIntegrationRichAlgorithmsComprehensiveScenarioCoverageEasyExpansionDiverseHardwareFormsSafety Production Algorithm All-in-One UnitDevice ManagementPreview ManagementConfigurationManagementEvent ManagementTask ManagementREST APIMQTT APIEnvironmentPersonnelMachineMaterialsMethod

全面质量管理4M1EAI Large Model ApplicationsFeaturesFlexibleIntegrationRichAlgorithmsComprehensiveScenarioCoverageEasyExpansionDiverseHardwareFormsSafety Production Algorithm All-in-One UnitDevice ManagementPreview ManagementConfigurationManagementEvent ManagementTask ManagementREST APIMQTT APIEnvironmentPersonnelMachineMaterialsMethod Electric VehicleDetectionVersion UpgradeThird-Party Algorithm IntegrationBased on sensors and network technologies, establishes real-time data acquisition and monitoring covering the five production elements of personnel, machines, materials, methods, and environment. It detects events and provides alarms via images and short videos, achieving full coverage of behavior, location, and operation scenarios, with multiple intelligent analysis algorithms to reduce false alarms.AI algorithms can be freely combined, accessed via proprietary protocols, and support third-party algorithms.Applicable to manufacturing enterprises and industries such as heavy processing, manufacturing, and logistics that require large-scale material or equipment lifting operations.

Electric VehicleDetectionVersion UpgradeThird-Party Algorithm IntegrationBased on sensors and network technologies, establishes real-time data acquisition and monitoring covering the five production elements of personnel, machines, materials, methods, and environment. It detects events and provides alarms via images and short videos, achieving full coverage of behavior, location, and operation scenarios, with multiple intelligent analysis algorithms to reduce false alarms.AI algorithms can be freely combined, accessed via proprietary protocols, and support third-party algorithms.Applicable to manufacturing enterprises and industries such as heavy processing, manufacturing, and logistics that require large-scale material or equipment lifting operations. -

Provides comprehensive management and maintenance services for various devices in factories and enterprisesFitow Intelligent Device Connectivity covers the entire device lifecycle with complete functions, ensuring each machine operates in optimal conditionUses scientific management methods to simplify complex equipment operation and maintenance into standardized and automated processesImproves work efficiency, reduces operation and maintenance costs, and more importantly, extends equipment lifespan, enabling enterprises to maintain strong competitiveness in intense market competition20% - 25%20% - 30%25% - 35%20% - 35%30% - 45%Reduced Spare Parts ConsumptionReduced Equipment Failure RateExtended EquipmentLifespanImproved Maintenance EfficiencyProvides a comprehensive management and maintenance solution for various devices in factories and enterprises. From inspection to repair, from maintenance to spare parts management, Fitow Intelligent Device Connectivity covers the entire device lifecycle with complete functions, ensuring every machine operates in optimal condition.By applying mature industrial AI models, device status data, fault maintenance records, and device threshold rules are input into fault algorithm models to detect abnormal device states and predict trends, ultimately outputting specific device faults, significantly improving maintenance efficiency and reducing failure rates.Reduced Maintenance Costs

Provides comprehensive management and maintenance services for various devices in factories and enterprisesFitow Intelligent Device Connectivity covers the entire device lifecycle with complete functions, ensuring each machine operates in optimal conditionUses scientific management methods to simplify complex equipment operation and maintenance into standardized and automated processesImproves work efficiency, reduces operation and maintenance costs, and more importantly, extends equipment lifespan, enabling enterprises to maintain strong competitiveness in intense market competition20% - 25%20% - 30%25% - 35%20% - 35%30% - 45%Reduced Spare Parts ConsumptionReduced Equipment Failure RateExtended EquipmentLifespanImproved Maintenance EfficiencyProvides a comprehensive management and maintenance solution for various devices in factories and enterprises. From inspection to repair, from maintenance to spare parts management, Fitow Intelligent Device Connectivity covers the entire device lifecycle with complete functions, ensuring every machine operates in optimal condition.By applying mature industrial AI models, device status data, fault maintenance records, and device threshold rules are input into fault algorithm models to detect abnormal device states and predict trends, ultimately outputting specific device faults, significantly improving maintenance efficiency and reducing failure rates.Reduced Maintenance Costs

Product Services

Product Services

Full Lifecycle System Training

Full Lifecycle System Training

7×24 Online Expert Support

7×24 Online Expert Support

Regular Follow-Up

Regular Follow-Up

Introduces user training programs, help documentation, and customer support

Experts provide 7×24 online technical support to help customers promptly identify and resolve issues

Regular follow-ups identify platform improvement opportunities and actively respond to user needs with secondary configuration

Deepens data analysis and mining to help enterprises make accurate and rapid decisions

Integrates with technologies such as artificial intelligence, machine learning, and the Internet of Things to achieve advanced functional applications

Mines hidden trends in massive data and transforms them into valuable information

Provides intelligent solutions and services through data integration, analysis, and mining

Eliminates information silos and achieves integrated data management and sharing

Empowers Enterprise Digital Transformation

Enables centralized data storage, management, prediction, and analysis

Achieves device interconnection and intelligent control, promoting IoT applications

Application Results

Application Results

Service Industries

Service Industries

Industrial Sector

Industrial Sector

Manufacturing Equipment Industry

Manufacturing Equipment

Industry

Automotive Industry

Automotive Industry

Education Industry

Education Industry