High-Precision Online 3D Measurement System

High-Precision Online 3D Measurement System

Non-contact ScanningMicron-Level Ultra-High PrecisionUltra-Fast Scanning Speed

Non-contact Scanning

Micron-Level Ultra-High Precision

Ultra-Fast Scanning Speed

Product Introduction

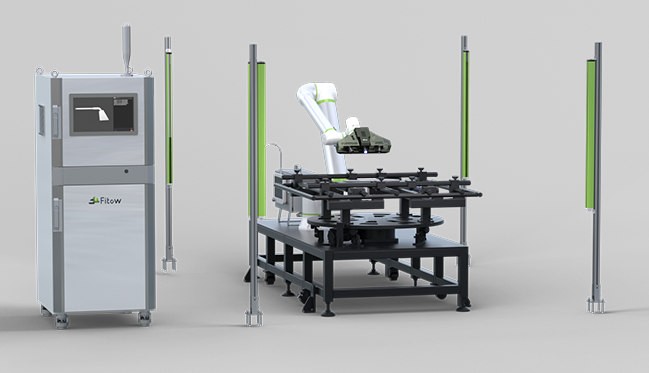

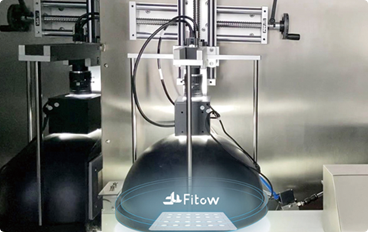

The High-Precision Online 3D Measurement System is capable of scanning irregular and standard curved surfaces, automatically generating 3D models in universal formats for design accuracy and consistency checks of complex geometries, including size, shape, position, and runout tolerance determination. Through high-precision scanning, 3D modeling, data analysis, and visualization, it ensures precise design and consistency of part surfaces, improving product quality and manufacturing efficiency.

Key Features

01 High-Precision Non-contact Optical 3D Scanning

02 No programming required to perform comparison and analysis of various shapes

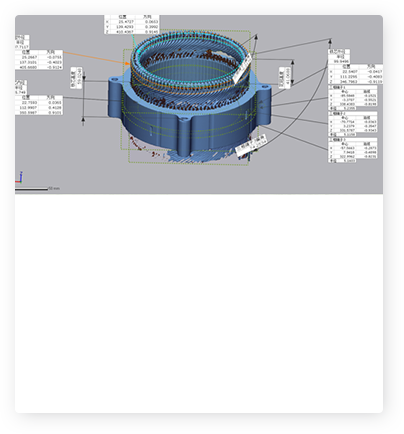

03 Align scanning data with the model, and present size and geometric tolerances on the interface

04 360° 3D Scanning After Placement

05 No need to change lenses or adjust focus

Performance

01 Measurement Accuracy

Accuracy of ±0.02mm for objects with dimensions smaller than 500mm

× 500mm × 500mm

Accuracy of ±0.05mm for objects with dimensions smaller than

1000mm × 1000mm × 1000mm

02 Measurement Speed

Single data collection time ≤ 1s, single scan time (including robotic arm

movement) ≤ 8s, data processing time 2~5min

For example, in measuring a specific airspeed tube, 12 scans are taken in one measurement, with a scan time of approximately 2 minutes and data processing time of 2-3 minutes, completing complex surface measurements in under 5 minutes

Accuracy of ±0.01mm for objects with dimensions smaller than 200mm × 200mm × 200mm

Product Functions

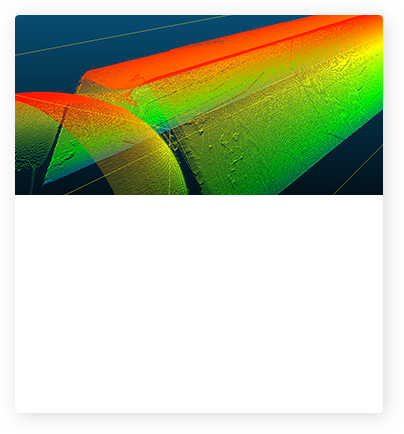

Surface Reconstruction

Scans irregular and standard curved surfaces, automatically generating 3D models in universal formats for design accuracy and consistency checks of complex geometries.

Dimensional Measurement

Easily perform 3D measurement with just a click of the data, obtaining complete measurements even for hard-to-reach areas. Only one scan is required to conduct multiple measurements.

Geometric Tolerance

Complete shape scanning allows measurement of shape, direction, position, and runout tolerances. Reference planes can also be set for simpler surface flatness measurements.

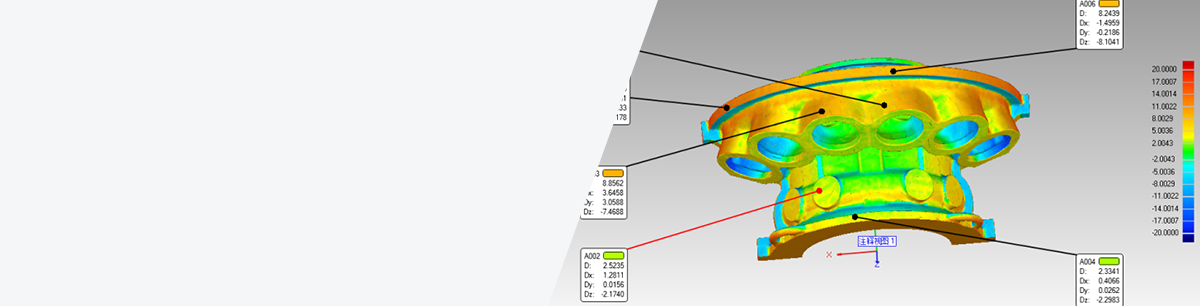

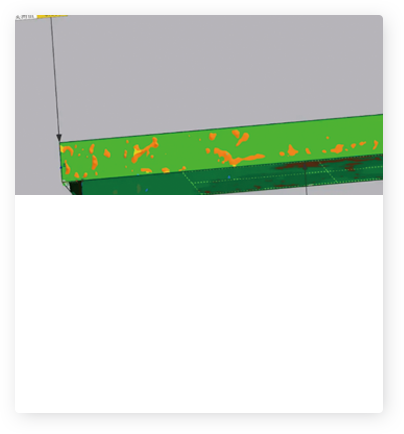

CAD Comparison Function

Comparison measurements can be made based on CAD data. The comparison fitting algorithm is updated for stable measurements, and measurements can also be compared based on CAD coordinates.

Product Comparison Function

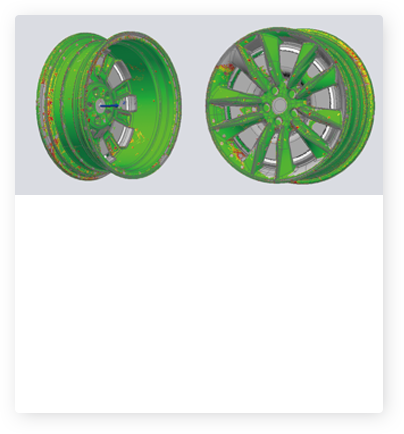

Differential Color Area Ratio Function

Visualization of differences through color, further quantifying the differences by displaying the area ratio for each color in numerical values. This allows for both visual and quantitative evaluation.

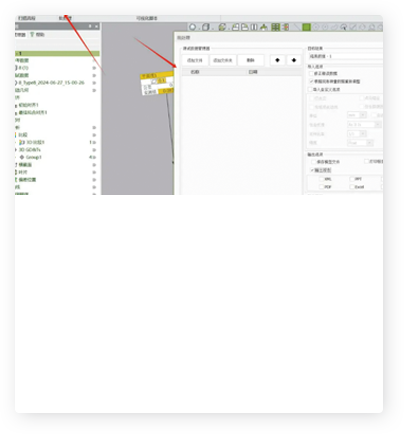

Template Function and Tolerance Determination Function

For multiple workpieces, the same measurements need to be repeated, and measurement errors may occur due to the measurement method. By setting tolerance ranges, it can determine whether the measurements are within tolerance.

Reverse Projection Function

Compare numerical models and actual samples using the 3D comparison function, marking defect locations on the scan data.

To summarize measurement results, the data obtained from the measurement system can be transcribed into Excel for generating company-specific reports. This system can output results in a specified Excel format, reducing editing time.

Export Excel Report

Compare two product datasets by overlapping them, visualizing shape differences through color, and using left-right reversal functionality to verify symmetry.

Product Specifications

Application Scenarios

Automotive Manufacturing

Aerospace Industry

Precision Engineering

Technical Service

Quick Response

Full Tracking