Fully Automatic Intelligent Lamp Inspection Machine

Fully Automatic Intelligent Lamp

Inspection Machine

AI Vision Deep Learning360° Full Inspection of Bottle AppearancePrecise Compliance with GMP Standards

AI Vision Deep Learning

360° Full Inspection of Bottle Appearance

Precise Compliance with GMP Standards

Product Introduction

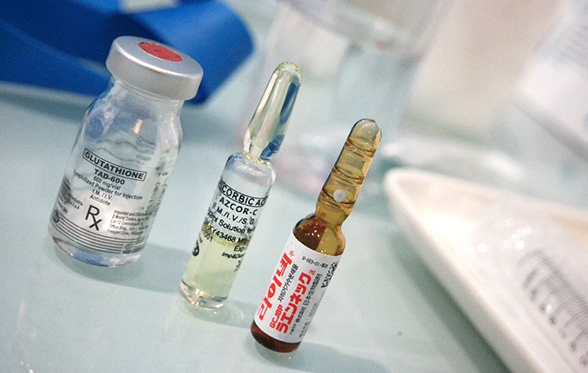

The Fully Automatic Intelligent Lamp Inspection Machine is designed for the full-process quality inspection of injectable pharmaceuticals (such as prefilled syringes, vials, and ampoules). Its core functions include filling and sealing integrity testing, foreign object detection, and visual inspection. By replacing traditional manual sampling with intelligent technology, it strictly follows the new GMP standards for "visible foreign objects" and other minute defects, ensuring products meet the stringent quality requirements necessary for direct human injection.

Key Features

High Integration: The inspection equipment integrates different workstations for inspecting the product's appearance and residual oxygen

High Precision Detection: Uses advanced image recognition and processing technology to accurately detect product appearance defects and residual oxygen content that does not meet standards

Efficiency: Automated inspection process significantly increases detection efficiency, helping companies improve quality and productivity

Easy to Operate: User-friendly interface for easy training and operation

Rich Variety of Defects Detected: Supports 360° appearance inspection of vials and ampoules, as well as residual oxygen content detection

Performance

Inspection Speed:400~600pcs/min Inspection Accuracy:0.1mm

Cap Sealing Inspection

1.Cap Missing Detection

2.Cap Position/Breakage/Impact Detection

3.Cap Curling Detection

4.Cap Color Detection

Sealing Integrity Testing

1. Powder (lyophilized powder) height, surface foreign objects, shape, cracks, etc.

2. Fill Level Inspection: product color, foreign objects, height, bottle bottom scratches, bottle bottom impurities

Bottle Body Inspection

1.Glass Cracks and Defects

2.Glass Scratch Detection

3.Detection of Same-Color and Different-Color Foreign Objects

4.Bubble Detection

Sealing Integrity Testing

1. Non-destructive testing based on tunable laser absorption spectroscopy technology

2. Low power consumption, small size, easy integration with lamp inspection machines/linked lines

3. Supports 2R-50R specifications

4. Maximum inspection speed: 600 bottles per minute

5. No nitrogen purging required

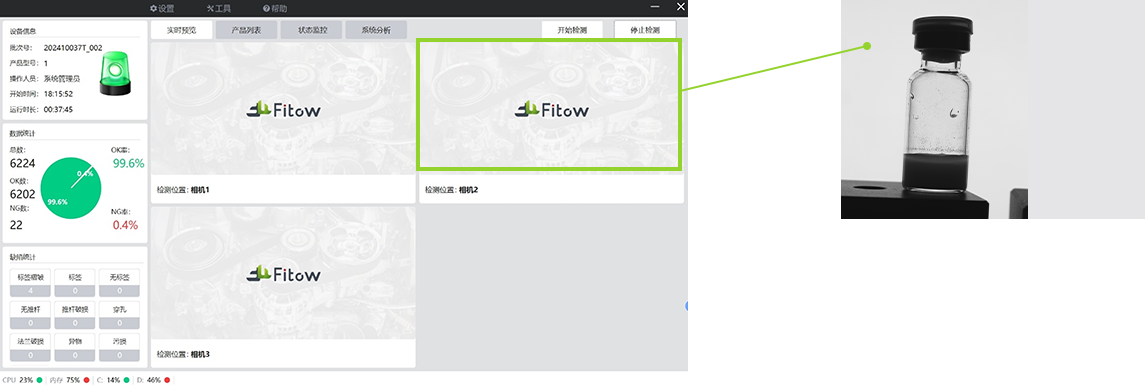

Software Introduction

The software system includes modules for data statistics, user management, camera and algorithm parameter adjustment, data querying, and report export, making it easy for customers to use.

User Management

Audit Trail

Query Inspection Data

Integrates with MES System

Product Advantages

Compatible with Various

Product Specifications

Algorithm Upgrades for Improved Performance

Straightforward Structure for Simplicity

Easy Maintenance, Lower Cost

Technical Service

Quick Response

Full Tracking