Final Assembly Configuration Verification System

Final Assembly Configuration

Verification System

Comprehensive Detection of Misassembly and Missing PartsMeets High-Cycle-Time and Multi-Position Inspection Requirements

Comprehensive Detection of Misassembly and Missing Parts

Meets High-Cycle-Time and Multi-Position Inspection Requirements

-

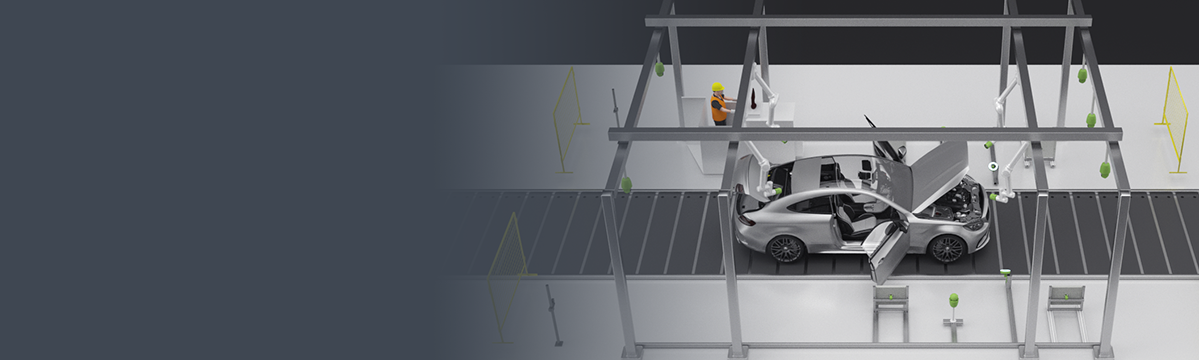

Used for assembly process verification in automotive final assembly workshops. By comparing image acquisition and processing results with QR code information, the system prevents configuration errors between different trim levels, reduces rework time and cost, and improves intelligent manufacturing capability.

-

Inline inspection with data interaction with other production line systemsVerifies interior and exterior configurations against the vehicle configurationlist, including chassis trim level and defect inspectionEnables configuration verification for mixed-model production in finalassembly workshopsHighly integrated system enabling intelligent inspection for flexible productionFully paperless process with inspection results pushed to APP and PADdevices; supports online records after rework, enabling online data traceabilityand inquiry

Inline inspection with data interaction with other production line systemsVerifies interior and exterior configurations against the vehicle configurationlist, including chassis trim level and defect inspectionEnables configuration verification for mixed-model production in finalassembly workshopsHighly integrated system enabling intelligent inspection for flexible productionFully paperless process with inspection results pushed to APP and PADdevices; supports online records after rework, enabling online data traceabilityand inquiry -

滚道磨伤异常01030402

High Efficiency: Using machine vision technology and AI algorithms, the system quickly and accurately detects misassembly and missing parts of vehicle exterior, interior, chassis, and wheels, as well as the quality of lamps and windshield washer nozzles.Accuracy and Reliability: Precisely identifies whether automotive components are correctly installed, detecting minor assembly errors, defects, or omissions to ensure every vehicle meets quality standards and reduce misassembly and missing-part issues.Flexibility and Adaptability: Can be customized and adapted to different vehicle models and variants to meet production line requirements, enabling rapid adjustment to various inspection needs.Data Analysis and Traceability: Performs real-time misassembly and missing-part detection while collecting, recording, and analyzing large volumes of inspection data for production line optimization, quality improvement, and troubleshooting. Enables traceability of each vehicle’s assembly history and quality data for better production management and control.

High Efficiency: Using machine vision technology and AI algorithms, the system quickly and accurately detects misassembly and missing parts of vehicle exterior, interior, chassis, and wheels, as well as the quality of lamps and windshield washer nozzles.Accuracy and Reliability: Precisely identifies whether automotive components are correctly installed, detecting minor assembly errors, defects, or omissions to ensure every vehicle meets quality standards and reduce misassembly and missing-part issues.Flexibility and Adaptability: Can be customized and adapted to different vehicle models and variants to meet production line requirements, enabling rapid adjustment to various inspection needs.Data Analysis and Traceability: Performs real-time misassembly and missing-part detection while collecting, recording, and analyzing large volumes of inspection data for production line optimization, quality improvement, and troubleshooting. Enables traceability of each vehicle’s assembly history and quality data for better production management and control. -

-

01.02.During ProductionSupports real-time viewing of inspectiondata, inspection results, and inspectionimages.After ProductionSupports data statistics, recording, and traceabilityafter production. Each inspection record is stored inthe system, and valuable inspection data can beshared with other production systems according toactual data requirements.

01.02.During ProductionSupports real-time viewing of inspectiondata, inspection results, and inspectionimages.After ProductionSupports data statistics, recording, and traceabilityafter production. Each inspection record is stored inthe system, and valuable inspection data can beshared with other production systems according toactual data requirements.

Technical Service

Quick Response

Full Tracking