Spindle Appearance Inspection

Spindle Appearance Inspection

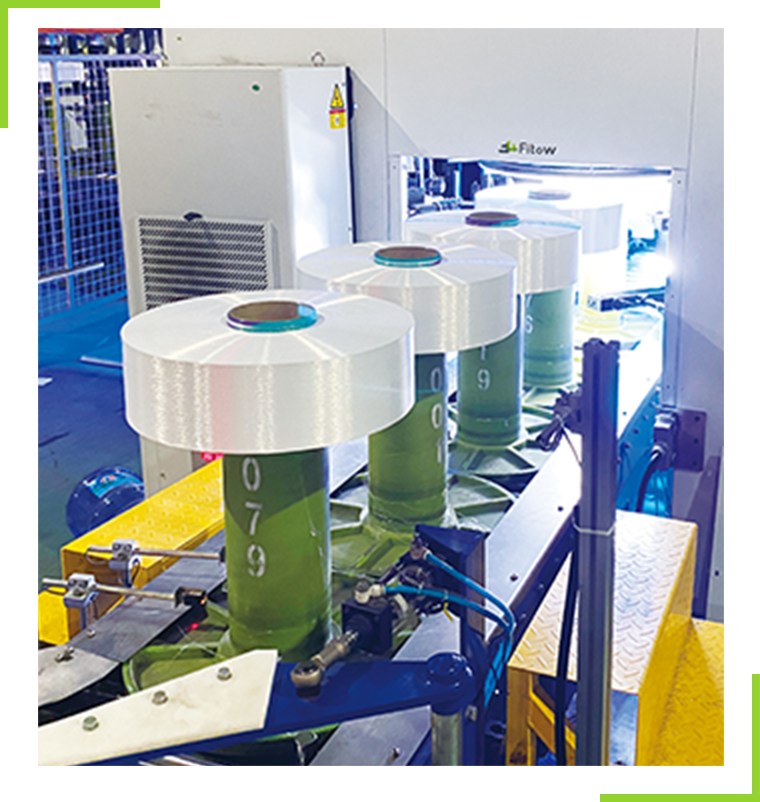

New Spindle Appearance Inspection System for On-loom DetectionFlexible equipment layout, strong compatibility, and small footprintReduces manual labor and improves defect detection accuracy on spindle surfaces

New Spindle Appearance Inspection System for On-loom Detection

Flexible equipment layout, strong compatibility, and small footprint

Reduces manual labor and improves defect detection accuracy on spindle surfaces

-

Used for exposed surface detection of spindles in the synthetic fiber industry, this system can be directly installed on the loom, improving detection efficiency, reducing manual handling, minimizing fatigue and missed inspections caused by human eyes, and providing complete quality traceability management.

-

More aligned with the synthetic fiber production process: The system can be laid outaccording to quality inspection workflows, enabling timely identification of productionquality defects and removal of defective products.Excellent specification compatibility: Adapts to changes in spindle size specifications,with automatic specification switching based on upper-level system data for seamlesstransition.Excellent defect detection: Optimized design for existing challenges in detecting fiberhair, achieving effective detection of fiber hair defects.High detection efficiency: 16s for single-line detection, with a complete 32-spindle loominspection in 72sLow total cost: Small footprint and minimal auxiliary equipment required, significantlyreducing overall equipment investment cost.Excellent human-machine collaboration: Clear and intuitive interface providing effectiveguidance for re-inspection by quality control workers.Good expandability: Optional functional modules can be selected for upgrading basedon specific inspection needs, with expansion capabilities for both equipment and technology.

More aligned with the synthetic fiber production process: The system can be laid outaccording to quality inspection workflows, enabling timely identification of productionquality defects and removal of defective products.Excellent specification compatibility: Adapts to changes in spindle size specifications,with automatic specification switching based on upper-level system data for seamlesstransition.Excellent defect detection: Optimized design for existing challenges in detecting fiberhair, achieving effective detection of fiber hair defects.High detection efficiency: 16s for single-line detection, with a complete 32-spindle loominspection in 72sLow total cost: Small footprint and minimal auxiliary equipment required, significantlyreducing overall equipment investment cost.Excellent human-machine collaboration: Clear and intuitive interface providing effectiveguidance for re-inspection by quality control workers.Good expandability: Optional functional modules can be selected for upgrading basedon specific inspection needs, with expansion capabilities for both equipment and technology. -

Inspection AccuracyApplicable to Spindle Types15s for single-line spindle inspection, 2.5s per spindlePolyester, Nylon, Spandex, Industrial Spindles, etc.

Fiber HairWaste fiber introduction,fiber entanglement, and knotsPresence of tail fibersMolding abnormalities/defectsPaper tube damagePaper tube color (same batch color abnormalities)Fiber entanglementCuts, scratches, impacts, and indentationsFiber collisionMachine-induced fiber collisionOil stains

Fiber HairWaste fiber introduction,fiber entanglement, and knotsPresence of tail fibersMolding abnormalities/defectsPaper tube damagePaper tube color (same batch color abnormalities)Fiber entanglementCuts, scratches, impacts, and indentationsFiber collisionMachine-induced fiber collisionOil stains -

-

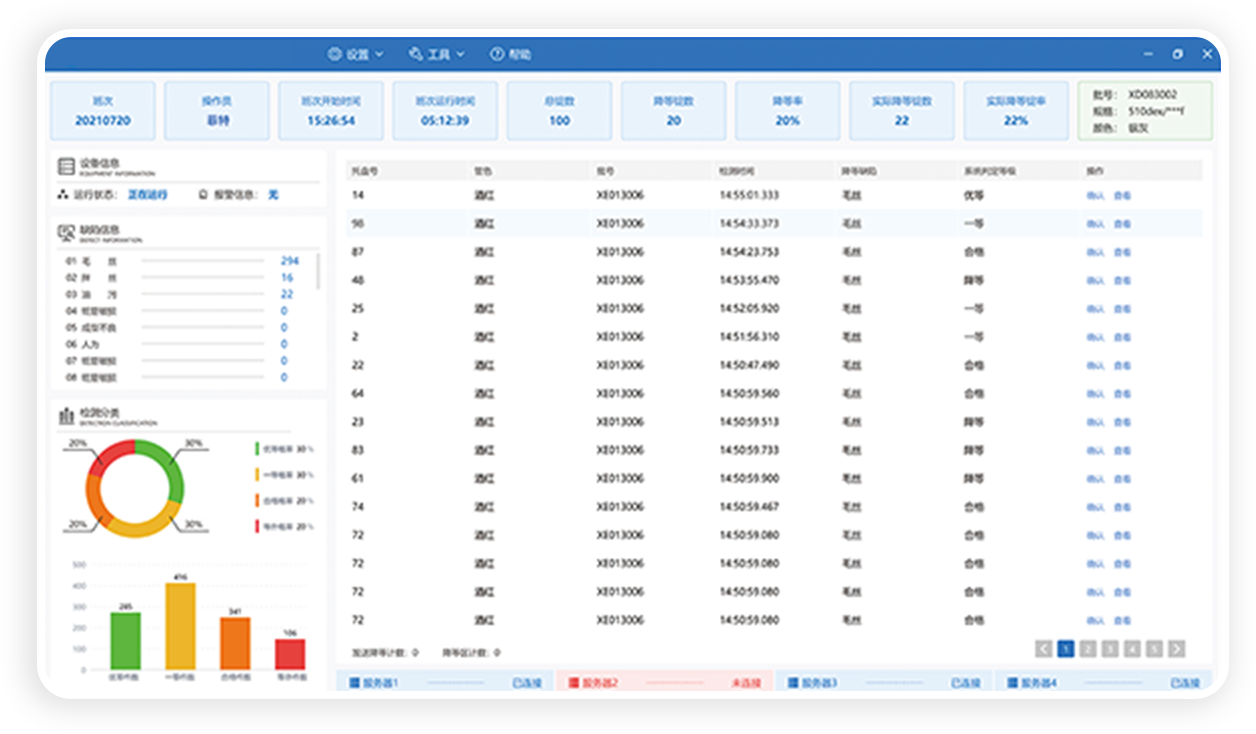

01.02.03.04.Real-time display of inspection status and defect countCapable of defect quantity statistics, defect type statistics,and intelligent classification of productsQuality management system available for real-timemonitoring of production quality informationSupports data export, providing defect traceability forproduction processes

01.02.03.04.Real-time display of inspection status and defect countCapable of defect quantity statistics, defect type statistics,and intelligent classification of productsQuality management system available for real-timemonitoring of production quality informationSupports data export, providing defect traceability forproduction processes

Technical Service

Quick Response

Full Tracking