Fully Automatic Lamp Inspection Module

Fully Automatic Lamp Inspection Module

AI Vision Deep Learning AlgorithmFull-Spectrum Defect Recognition Before and After CoatingReal-time Defective Product Rejection

AI Vision Deep Learning Algorithm

Full-Spectrum Defect Recognition Before and After Coating

Real-time Defective Product Rejection

The Fully Automatic Lamp Inspection Module is dedicated to the packaging appearance quality inspection of solid dosage forms (tablets, capsules, etc.) and liquid dosage forms (prefilled syringes, vials, ampoules, etc.). By integrating a vision module and deep learning algorithm, it enables automated in-line inspection on high-speed production lines, covering full-spectrum defect detection on the front and back of blister packs before and after coating. The system rejects defective products in real-time, ensuring compliance with GMP regulations and high-quality standards. It also addresses the challenges of high error rates, non-traceable data, and high costs associated with traditional manual inspection, helping pharmaceutical companies enhance their quality control capabilities.

Product Introduction

Key Features

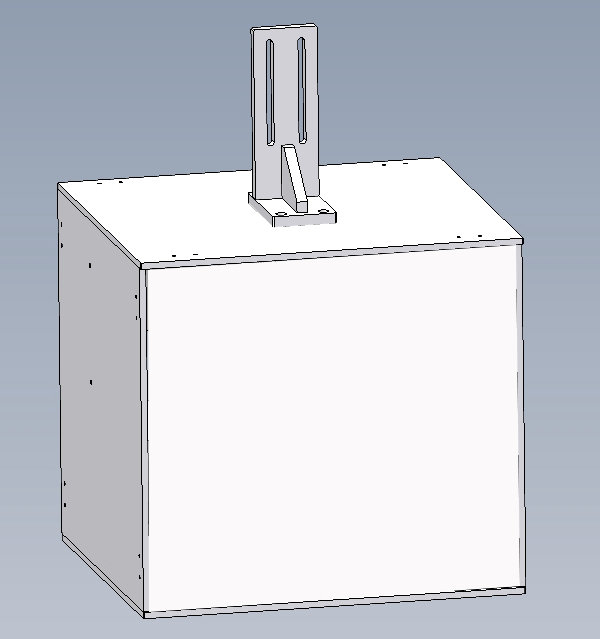

High Integration: The camera vision system, light source system, and control system are integrated into the module, effectively saving installation space and improving installation efficiency.

High Precision Detection: Uses advanced image recognition and processing technology to accurately detect the appearance defects of blister pack products.

Rich Variety of Defects Detected: Supports detection of defects in both solid and liquid dosage forms.

Easy to Operate: User-friendly interface for easy training and operation.

Efficiency: Automated inspection process significantly increases detection efficiency, helping companies improve quality and productivity.

Performance

Inspection Speed: 400~600 pcs/min Inspection Accuracy: 0.5mm

Liquid Dosage Form Detection

Detectable defects include pre/post-coating, no push rod, label wrinkles, missing labels, no product, no liquid, needle misalignment, etc.

Defective products are rejected by the added reject mechanism.

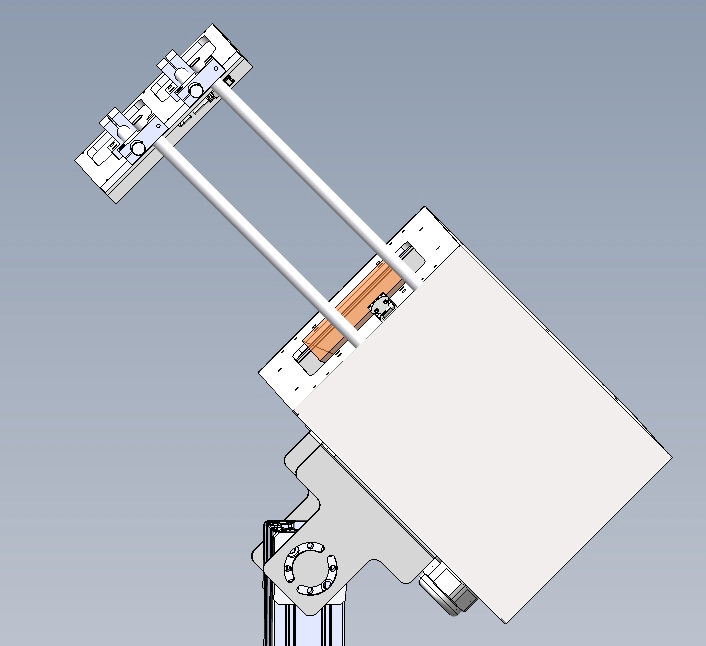

Liquid Dosage Form Detection Scheme

Reject Station: Pneumatic reject mechanism to remove defective products

Station 2: Post-coating detection of blister pack front

The above example is for the visual inspection of prefilled syringe blister pack appearance. By installing the vision module, both the front and back of pre/post-coating blister packs are photographed and inspected, with defective products being rejected in real-time.

Station 1: Pre-coating detection of blister pack backside

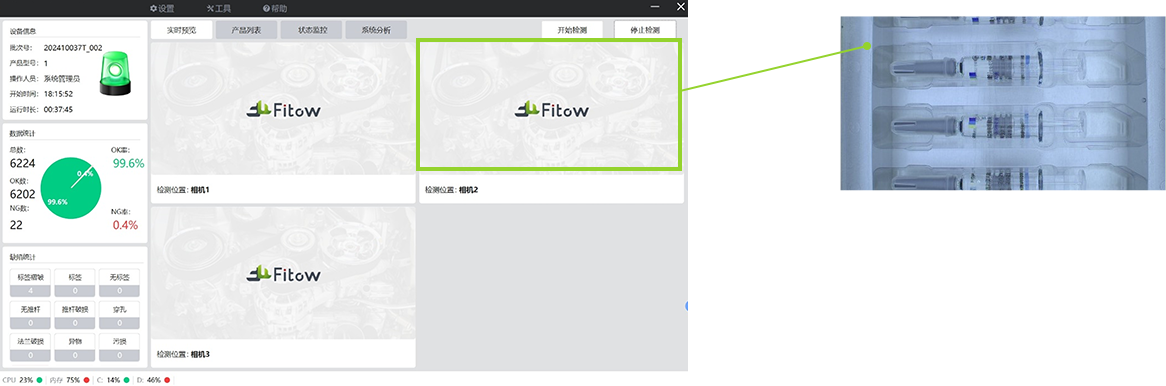

Software Introduction

The software system includes modules for data statistics, user management, camera and algorithm parameter adjustments, data querying, and report exporting, making it user-friendly for clients.

Defect Information Recording

Information Traceability

View Detected Defect Images

Integrates with MES System

Product Advantages

Traditional Lamp Inspection

Pharmaceutical Blister Packaging Appearance Quality Inspection Module

Traditional lamp inspection machines primarily detect content defects, and cannot detect defects in subsequent packaging processes.

The pharmaceutical blister packaging appearance quality inspection module performs inspection during the blister packaging process, effectively addressing the shortcomings of traditional lamp inspection.

The pharmaceutical blister packaging appearance quality inspection module offers high flexibility in installation and can be directly mounted on existing production lines, saving investment costs.

Traditional lamp inspection machines have complex structures, are standalone devices, and require complex installation and debugging, resulting in high investment costs.

Technical Service

Quick Response

Full Tracking